Medical endoscope solution development

The application of endoscopes is quite extensive in the treatment of diseases related to the ENT (ear, nose and throat). The endoscope we designed for use in the ear can well meet the current otological applications, and the designed resolution reaches 100lp/mm. The image is clear and can fully meet the medical application of ear science. The main function of the endoscope is to determine and observe the diseased tissue, and carry out early diagnosis and treatment [1-2]. Endoscopy is widely used in the diagnosis and treatment of otolaryngology (otolaryngology) diseases [3-4]. Early ENT instruments include otoscopes, indirect nasopharyngoscopes, indirect laryngoscopes, etc., which belong to the first generation of products. The second generation products integrate these equipment and equipment. With the development of science and technology, digital high-definition ENT endoscopic diagnosis and treatment workstations have emerged, which can provide high-definition ENT endoscopic videos. In recent years, otoscopes have become more and more widely used in clinical otology. It inserts the observation probe into the ear, and under the illumination of its own light source, there is an imaging lens to capture the details of the ear, which is imaged on a CMOS or CCD image sensor. After photoelectric conversion and image signal processing, it is sent to the monitor for clear display. The enlarged image is for the doctor to observe. At present, most otoscopes on the market are products distributed by foreign companies, and there are very few independently developed otoscopes.

1. Design ideas

1.1 Selection of initial structure

Reasonable selection of the initial structure can lead to a good lens, and it directly affects whether the design can proceed smoothly. There are two methods for designers to choose from. One is to design an initial structure using paraxial optical principles through the designer's experience, and then gradually adjust the structural parameters to obtain the required results. However, it is very difficult to rely solely on designers to create an initial mechanism, which requires designers to have certain work experience and rich theoretical reserves. Another method is to select a suitable initial structure from relevant literature and patents for optical design, and then optimize it. The initial structure of this design uses a US patent as the starting point for the design. The selection principle of the initial structure is that the aperture value is the same as the field of view and design index requirements, and the focal length can be achieved by scaling the lens size.

2. Design process

2.1 Input of initial structure After selecting the corresponding initial structure, it is necessary to modify all aspects of the initial structure. Through the scaling of the focal length and the input of wavelength, field of view, and F number, the initial structure can reach a basic size requirement. . First, zoom the focal length to 1.3mm, and then set the F number to 7.65. This article uses the field of view angle to control the field of view, and input the field of view and wavelength as well as the lens parameters of the initial structure into Zemax [5].

3. Design results

The optimized appearance structure and system parameters of the lens are shown in Figure 1 and Table 1. The system is composed of 10 lenses, including two sets of doublet lenses, two lenticular lenses, one meniscus lens, one lenticular lens, and one flat lens. The glass materials from the first piece to the last piece are: H-ZF62, H-LAF10L, H-LAK53A, H-ZLAF75A, H-ZLAF53A, H-LAK2, H-ZF7LA, K9, F5, BAF8. The combination of crown glass and flint glass is helpful in correcting aberrations.

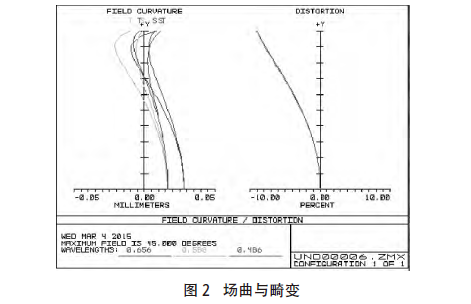

3.1 Field curvature and distortion

Field curvature reflects the curvature of the image plane of the entire optical system. For this type of endoscopic lens, the field curvature is less than 0.2 mm. As can be seen from Figure 2, the field curvature is corrected within 0.05 mm. In addition, for this low-cost endoscope lens, the distortion requirements are relatively low. As can be seen from Figure 2, the edge field of view distortion is within 10%. At a field of view of 0.7, the distortion is about 5%, which meets the design requirements.

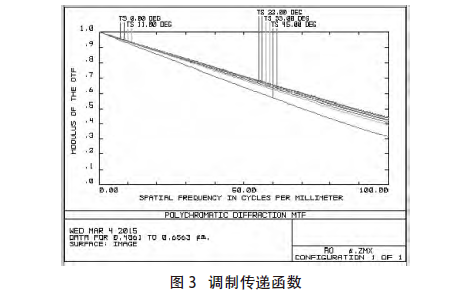

3.2 Modulation transfer function

The modulation transfer function (MTF) is the degree of attenuation of the contrast (that is, the amplitude) of the sinusoidal intensity distribution function of various frequencies after being imaged by the optical system. For visual systems, the threshold of the human eye is 0.3, and for camera systems, the threshold is 0.1. As shown in Figure 3, at 100lp/mm, all fields of view are greater than 0.3. Meet the design requirements [7-8].

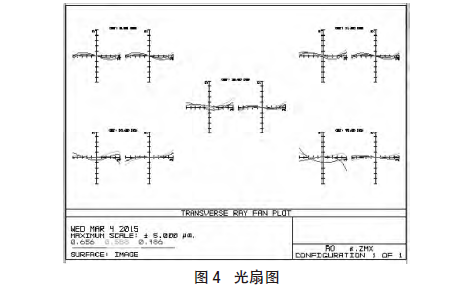

3.3 Light fan diagram

The light fan diagram is about the ray aberration of the pupil coordinate function. The drawing data is the difference between the coordinates of the intersection point of the ray and the image plane and the coordinates of the intersection point of the chief ray and the plane. They can well reflect the actual convergence of light on the image surface [9]. As shown in Figure 4, the light convergence is relatively good.

3.4 Point diagram

It can be seen from Figure 5 and Figure 6 that the root mean square radius of the imaging diffusion spot in each field of view of the system is much smaller than the Airy disk radius, and the energy is relatively concentrated, which meets the design requirements.

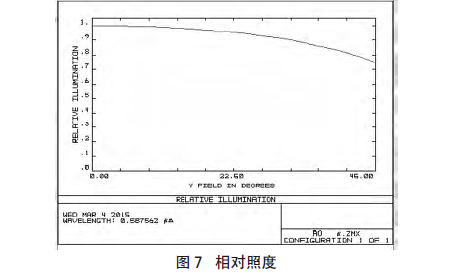

3.5 Relative illumination

Relative illumination refers to the ratio of the illumination at the edge of the field of view to the illumination at the center. The higher the ratio, the brighter the edge. Generally speaking, a relative illumination above 50% is acceptable. As can be seen from Figure 7, the relative illumination of this lens is above 70%, which meets the design requirements.

4. Tolerance analysis

4.1 Tolerance analysis method

In order to improve the imaging quality of this optical system, all parameters in the system need to be assigned variable tolerances. If the system fluctuates greatly or is more sensitive to changes in one of the parameters, the system needs a relatively high level of performance. Therefore, for The tolerance requirements of this group should be tight, whereas looser tolerances can be applied. Sight glasses have relatively high requirements for imaging, so the requirements for the tolerance of the optical system are relatively strict. Use the tolerance calculation and analysis program in the ZEMAX software to calculate the sensitivity of performance degradation of various parameters in the optical system, that is, to analyze the processing and assembly tolerances of all components.

4.2 Results of Tolerance Assignment

Using ZEMAX optical design software, through sensitivity analysis, inversion sensitivity analysis and Monte Carlo analysis, the reasonable tolerance distribution of the microscope objective lens is obtained. By calculating and analyzing the MTF drop of each tolerance parameter at the Nyquist spatial frequency of 100lp/mm, the appropriate tolerance is finally determined. The results of sensitivity tolerance analysis and Monte Carlo tolerance analysis are shown in Table 2 and Table 3 respectively. The results of Monte Carlo tolerance analysis show that more than 90% of the microscope objective system has a Monte Carlo sample MTF0.156524163, and each sample is a simulated processed and adjusted optical system.

Summary

By establishing the ideal initial state and initial structure of the optical system, the Zemax optical design software is used to optimize the structure design, and then an endoscopic lens that meets industrial standards and can be produced is obtained. Compared with other similar lenses, this lens has better distortion control at a 90° field of view, and a resolution of 100lp/mm, which is more conducive to observing diseased tissues. In summary, this endoscope meets medical needs.

Proposal recommendation

- TOP