- Home >> Solution >> Appliances >> home appliances

Heater program

1. Brief Introduction of Portable Heater

With the progress of the times, people's living standards have also been significantly improved. In the cold winter before, people could only burn coal in their own homes for heating, which had a certain impact on people's respiratory health, and the temperature in the house was sometimes relatively high. Low. In modern times, there are various heating methods, and people can feel the warm temperature in the house as long as they pay the heating fee, without any impact on their own health. However, it is inevitable that the heating effect is unsatisfactory. Therefore, heaters have been developed to help people survive the cold winter. Portable heaters are small in size, light in weight, and easy to use, and are deeply loved by consumers.

2.The classification of portable heaters

There are six main types of portable heaters: bosom heaters, rechargeable hot water bottles, oil-filled electric heaters, PTC heaters, convection heaters, and electrothermal film heaters.

(1) Heart furnace: What is a heart furnace? It sounds like it will only appear in yellowed books. Hand warmer, also known as hand warmer, is the smallest portable heater, suitable for warming hands and feet, neuralgia, cold, rheumatism and back pain. The body furnace mainly generates heat by burning oil, and the body of the furnace is used as a container for storing oil. Some high-quality body furnaces can be used for 8 hours without cooling down with two or two oils, but care must be taken to prevent oil leakage from causing danger during use.

(2) Rechargeable hot water bag: In the past, people relied on hot water bags to keep warm. Before going to bed every day, fill the hot water bag with boiling water and put it into the bed, which can make the bed warmer and not feel cold to the touch. The invention of the rechargeable hot water bag solves the shortcoming of the ordinary hot water bag, which has a short heat preservation time and relies on boiling water for heating. The main control method of the rechargeable hot water bottle is electric heating wire heating, but if the electric heating hot water bag does not undergo multi-layer processing and the safety of its inner tank is done well, it is also prone to dangers such as electric leakage and explosion.

(3) Oil-filled electric heater: Oil-filled electric heater is also called electric heating heater, and the volume of this kind of electric heater is not very large. After it is powered on, it heats the surrounding new type of heat conduction oil through the heat pipe, and dissipates the heat from the heat pipe or the radiator, thereby increasing the temperature. When the internal oil temperature reaches 85 degrees, its temperature control system will automatically cut off power supply to prevent danger. Because the portable electric heater has high safety factor, long service life and convenient use, it is suitable for families with old people and children living at home. Although the oil-filled electric heater is easy to use and does not need to replace the heat transfer oil, its heat dissipation effect is not good, and it consumes a lot of electricity.

(4) PTC heater: PTC heater, as the name suggests, can blow out high-temperature wind to increase the heat in the air. PTC is an abbreviation for a ceramic heating element. Its temperature system uses a fan to agitate air to flow through the PTC heating element to force convection. The interior of the PTC heater is equipped with a temperature limiter. When the air outlet is blocked, it will automatically cut off the power supply, and some also use the method of dumping and powering off. PTC heaters generally have a good waterproof function, so they are more suitable for use in bathrooms. It has high safety performance, low price, and high cost performance. It is a popular portable heater in modern times.

(5) Convection heater: The top of the convection heater is the air outlet, and the bottom is the air inlet. After plugging in the power supply, the air around the electric heating tube is heated, and the gas rises and is discharged from the air outlet. At the same time, the surrounding cold air is discharged from the air inlet. This is the concept of the temperature system design of convection heating. It also has a certain degree of safety. When the outlet is blocked and the temperature rises rapidly, the temperature control element will automatically cut off the power. This kind of electric heater is very quiet, but the heating rate is slow.

(6) Electric heating film electric heater: electric heating film electric heater is currently the most advanced technology among portable heating. It uses a completely transparent electric heating film as the heating material, uses the structure of the hot air channel inside, adopts the method of enhanced convection, the temperature rises quickly, and it can reach more than 100 degrees within 3 minutes after starting up. Electric film electric heaters are generally small in size, long in service life, and novel in shape, and are one of the best-selling portable heaters.

3. Design of temperature control system for portable heater

The temperature control systems of today's portable heaters can be mainly divided into the following categories.

(1) Heating wire heating element: use the heating wire to generate heat, and then dissipate the generated heat through the fan, which is mainly used in the heater. After product upgrades and reforms, some portable electric heaters use reflected distance to dissipate the heat generated by the heating wire. Generally, the fuselage can rotate at a certain angle to provide multi-directional heating. At the same time, it also has advanced safety performance. It adopts a temperature control system that automatically cuts off the power when it is dumped or the temperature is too high.

(2) Quartz tube heating element: This type of product is composed of sealed electric heating elements, paraboloids or reflectors, protective strips and other basic components, with quartz radiant tubes as the main temperature control components, energy-saving technology for heating by far infrared rays, The infrared rays emitted by the infrared radiation can be absorbed by objects and directly turned into heat to achieve the purpose of heating. Because this technology is very advanced, and infrared rays can have a physiotherapy effect on the human body, it has always been one of the portable electric heaters that consumers like.

(3) Metal tube heating element: the same as the electric heating wire, similar to an electric fan. The principle of metal tube heating is adopted to use the reflective surface to dissipate the heat energy, so as to play the role of heating. The design of this temperature control system is longer and safer than heating wire heating. But its disadvantage is the same as that of the heating wire, it needs to work continuously, consumes a lot of power, and the temperature drops quickly after the power is turned off.

(4) Halogen tube heating element: Halogen tube is a closed luminous and heating tube with tungsten wire in the middle and filled with halogen element inert gas. The halogen tube generates heat and does not oxidize, so it has a long service life, fast heating speed and high work efficiency.

(5) Carbon fiber heating element: It is a tubular heating element made of carbon fiber, and the heat generated by carbon fiber is used to diffuse on the reflecting surface to achieve the purpose of heating. Such products generally use a single tube to generate heat, with fast temperature rise and high efficiency. However, compared with other portable products, the current heaters that use carbon fiber to generate heat are slightly larger.

At present, there are also temperature control systems such as heat conduction oil heating and ceramic heating on the market. Their heating principles are slightly different, and there are also certain differences in function and practical value. Consumers can choose the most practical portable heater according to their own needs.

4. Design of energy-saving remote control electric heater

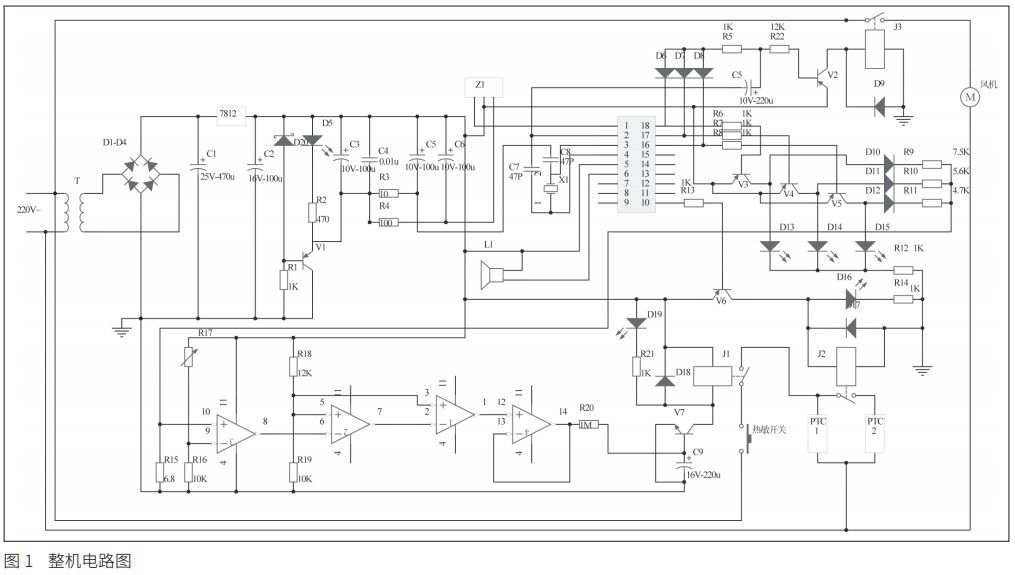

The electric heating heaters that are currently used in large quantities are manually controlled, with high power and high energy consumption. The energy-saving remote-controlled electric heater introduced in this article is controlled by infrared remote control, and several preset temperature values are set according to user requirements. When the room temperature during heating reaches the preset temperature, it will automatically cut off the power, and it will automatically heat up after the temperature drops, so as to achieve the effect of energy saving and comfort. The control system is composed of power supply circuit, main control circuit, remote control transmitter circuit, single threshold temperature control circuit, fan and waste heat dissipation protection circuit, etc. Its complete machine circuit is shown in Fig. 1.

4.1 Power circuit of electric heater

After the 220V power supply voltage is dropped by the transformer, it is rectified by the D1-D4 bridge and filtered by C1 to generate a voltage of about 19V, and then stabilized by the N3 (7812) three-terminal voltage regulator to obtain a 12V voltage, filtered by C2, and Zener diode D20 stabilized voltage value is 5.6V, since the voltage between the emitter and base of triode V1 is about 0.6~0.7V, so the voltage drop between the anode of D5 and the emitter of V1 is 5V, after C3, C4 The first-stage filtering, the second-stage filtering of R3 and C5 are supplied to the main chip N1, and the second-stage filtering of R4 and C6 is supplied to the receiving head Z1. It is worth noting that the 5V power supplies of N1 and Z1 are both suspended power supplies, that is to say, the negative pole is not connected to the ground of the power supply, but the negative terminal 2 pins are connected to 7V, the positive terminal 5 pins are connected to 12V, and the voltage difference is 5V, so as to realize 5V power supply.

4.2 The main control circuit of the energy-saving heater

The circuit is mainly controlled by PT2128A-C31 integrated chip. C7, C8, X1, and N1 form a 455KHZ crystal oscillator to generate the clock signal required for the chip to work. The receiving head Z1 receives the signal from the infrared remote control transmitter, amplifies, demodulates, and decodes it and sends it to pin 1 of PT2128A-C31. According to the information of the temperature preset value in the infrared remote control signal, pin 16, pin 17, One of the 18 pins must be low level, and the other two pins are high level. When pin 18 is at low level, through the resistor R6, the triode V3 is saturated and turned on, and its saturation voltage drop is 0.3V, and the conduction voltage drop of the diode D10 is 0.7V, so the negative voltage of D10 is 11V, which is divided by R9 and R15 Afterwards, it is sent to the 10-pin end of the LM324 with the same name. Similarly, when pin 17 is at low level, the triode V4 is saturated and turned on through resistor R7, and then through the voltage drop of diode D11, the voltage is divided by R10 and R15 to pin 10 of LM324. When pin 16 outputs a low level, the triode V5 is saturated and turned on through R8, the voltage is stepped down by diode D12, and then sent to pin 10 of LM324 through R11 and R15. These three voltages are the reference voltages for temperature setting.

When two sets of heating plates are required to be heated together, the infrared signal received by the receiving head Z1 is amplified, demodulated, and decoded and sent to pin 1 of the integrated block PT2128A-C31, and pin 10 of the PT2128A-C31 outputs a low level, and the triode V6 is activated by R13. Saturation conduction, relay J2 pulls in, PTC2 energizes and heats.

D6, D7, and D8 form an AND gate circuit. As long as one of the outputs is low, V2 will be turned on, J3 will have a current, the switch will be closed, and the fan will rotate to send out the heat of the PTC heating element in the heating state. , blowing hot air.

Whenever pin 1 of PT2128A-C31 receives an instruction from receiving head Z1, its pin 6 outputs a low level, and the buzzer L1 will beep once.

4.3 The remote control transmitting circuit of the heater

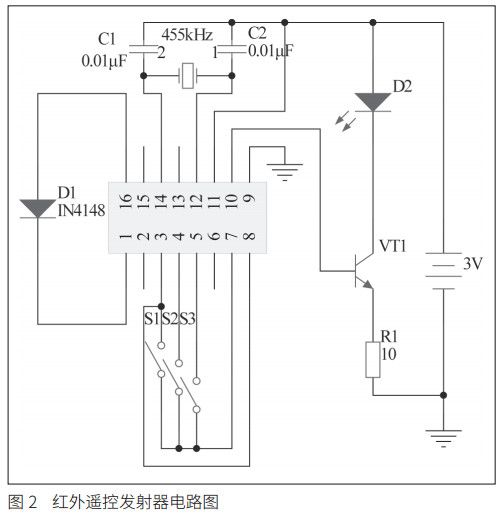

The infrared remote control transmitter is composed of PT2268 integrated circuit. The transmitted signal transmits the coded signal through the D2 infrared light-emitting diode SE303. Each transmission is twice, and one of them is reversed to prevent the receiver from receiving wrong codes. Infrared remote control transmitter circuit shown in Figure 2.

4.4 Energy-saving heater single-threshold temperature control circuit

The circuit is mainly composed of a temperature sampling circuit and a comparison control circuit. The temperature sampling circuit is mainly composed of R16 and R17, among which R17 is a negative temperature coefficient thermistor installed at the air inlet of the heater to sample the indoor temperature.

The comparison circuit is composed of LM324. After setting the indoor preset temperature for the heater, pin 10 of LM324 also sets a reference voltage accordingly. The sampling voltage generated by the sampling circuit is sent to pin 9 of LM324. When the indoor temperature does not reach the set temperature, the voltage of pin 10 of LM324 is greater than the voltage of pin 9, so pin 8 outputs high level, and pin 5 and pin 3 output fixed voltage. Level 5.5V, so pin 7 outputs low level and pin 1 outputs high level. The fourth op amp is connected as an emitter follower, so pin 14 also outputs a high level. At this time, the transistor V7 is turned on, the relay J1 is closed, and the heating plate starts to heat up. When the indoor temperature reaches the set temperature, the voltage of pin 10 of LM324 is lower than that of pin 9, pin 14 outputs low level, the triode V7 is cut off, the relay is disconnected, and the heating plate stops heating. But when the temperature drops a little, the comparator turns over, the relay pulls in, and the heating plate starts heating again. When the temperature reaches the set temperature, the comparator turns over again, the relay turns off, and the heating plate stops heating. The relay keeps beating in such a short period of time, which is easy to be damaged. To this end, an RC delay circuit composed of R20 and C9 is set up. First, the time required for the temperature in the room to drop by 2 degrees is tested through experiments, and then the RC delay circuit is designed by selecting resistors and capacitors according to the time. The control of temperature is converted into the control of time, so that when the indoor temperature is 2 degrees lower than the set temperature, the comparator will flip and the relay will start to jump, thereby reducing the frequency of relay jump and ensuring the relay The working life of the device realizes single-threshold temperature control.

4.5 Fan and waste heat dissipation protection circuit of electric heater

When the receiving head receives the power-on signal, one of the pins 16, 17, and 18 of the main chip is converted from a high level to a low level. Through the AND gate circuit, the base of the triode V2 is at a low level, and V2 is saturated and turned on. The relay pulls in, so that the fan starts to work. When the connector receives the shutdown signal, pins 16, 17, and 18 of the main chip are all at high level, and the base of the triode V2 is at a very high level through the AND gate circuit, the triode is in a cut-off state, the relay is disconnected, and the fan stops working.

Diodes D6, D7, D8 and resistor R5 form an AND gate circuit, so that when the heater operates in any of the three temperature ranges of low, medium and high, the AND gate circuit outputs a low level to ensure the correct operation and work of the fan circuit . Diode D9 is to protect the transistor V2, because when the transistor V2 changes from on to off, the current flowing through the relay coil will rapidly decrease from the maximum value to zero, and the coil will have a high self-inductance due to the sudden change of the current The electromotive force, superimposed with the power supply voltage, is between the C and E stages of the triode V2, which may cause the triode to break down. After the diode D9 is connected in parallel, the self-inductance electromotive force of the coil can be clamped at the forward conduction voltage of the diode, so as to avoid breakdown. wear diodes.

The residual heat dissipation protection circuit uses an RC delay circuit to delay the closing of the fan, so that the fan can continue to work for a period of time after the heater is turned off, and radiate heat to the heating plate of the heater and the plastic device nearby to prevent them from being overheated. damage. When the receiving head receives the shutdown signal, the three pins 16, 17, and 18 of the main chip all change from low level to high level, and C10 is considered to be low level because the voltage at both ends cannot change suddenly, so the base of the triode V2 Still at low level, the triode V2 is still conducting, so the relay J3 is still closed, and the fan continues to rotate, thereby dissipating heat to the heating plate of the heater. At this time, the 12V voltage of the emitter of the triode charges C10 through the E and B poles of the triode V2 and the resistor R22. When the capacitor C10 is fully charged, the triode V2 is cut off, the relay is disconnected, and the fan stops working. The length of time for the delayed operation of the fan is determined by the time constant of resistor R22 and capacitor C10. Changing the value of capacitor C10 or resistor R22 can change the length of the delay time. Increase the value of capacitor C10 and resistor R22 to increase the delay time. On the contrary, the delay time becomes shorter.

Summarize

The energy-saving remote control electric heater is designed with an automatic temperature control and protection system, which is suitable for the upgrading of ordinary electric heaters. The temperature automatic control system is set by the remote transmitter to control the temperature, and the sensor samples and compares with the set value to analyze and determine the working state of the heater, which is different from the traditional double threshold control circuit. The system is realized by a single threshold judgment and temperature-time conversion circuit, which optimizes and simplifies the circuit. The design idea of the fan automatic delay protection function of the protection system is novel, simple and convenient, with low overall cost, complete functions, and high performance-price ratio. It has high practical value.

In my country, the market for small home appliances has begun to take shape, and consumers' demand for portable heaters has increased significantly. Therefore, innovation and research on portable heaters must be strengthened to produce safer, more effective, more convenient and quicker heating products.

The above are the details of the portable heater solution introduced by Shenzhen Zuchuang Microelectronics Co., Ltd. for you. If you have the development needs of energy-saving remote control electric heaters, you can trust us. We have rich experience in customized development of electronic products. We can evaluate the development cycle and IC price as soon as possible, and can also calculate the PCBA quotation. We are a number of chip agents at home and abroad: Songhan, Yingguang, Jieli, Ankai, Quanzhi, realtek, with MCU, voice IC, Bluetooth IC and module, wifi module. Our development capabilities cover PCB design, single-chip microcomputer development, Bluetooth technology development, software customization development, APP customization development, WeChat official account development and other hardware and software design. It can also undertake the research and development of smart electronic products, the design of household appliances, the development of beauty equipment, the development of Internet of Things applications, the design of smart home solutions, the development of TWS earphones, the development of Bluetooth earphone speakers, the development of children's toys, and the development of electronic education products.

- TOP