- Home >> Solution >> Appliances >> home appliances

Disinfection machine program

The cleaning devices currently on the market are cumbersome and have a single function, which cannot achieve the desired cleaning effect. In this paper, a portable cleaning and disinfection all-in-one machine is designed by combining the principle of ultrasonic waves and bubble impact, which can not only remove dirt efficiently, but also reduce the use of cleaning agents. The ozone and UV germicidal lamp (UV/03) system is not only beneficial to environmental protection, but also can reduce the harm of detergent to human health. This portable cleaning and disinfection all-in-one machine is suitable for home travel and has obvious technical advantages.

1. The working principle of the portable cleaning and disinfecting machine

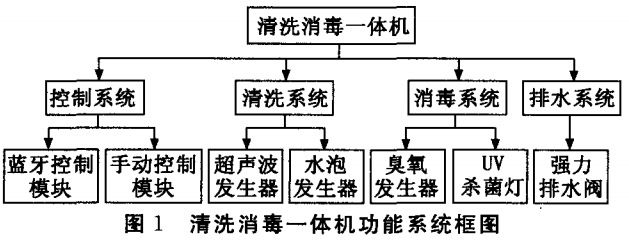

The functional system of the portable cleaning and disinfection all-in-one machine consists of four parts, namely the control system, cleaning system, disinfection system and drainage system, as shown in Figure 1. Among them, the control system realizes wireless and manual control through the Bluetooth control module and the manual module; the cleaning system improves the cleaning efficiency through the high-frequency vibration generated by the ultrasonic generator and the bubble impact principle; the disinfection system realizes the disinfection of residual drugs through the ozone generator and UV sterilization lamp degradation; the drainage system realizes drainage through a strong drainage valve, so that there is no residual waste water in the all-in-one machine.

1.1 The principle of ultrasonic cleaning

The basic working principle of ultrasonic cleaning is: the power frequency alternating current is converted into a high frequency alternating current signal through the switching action of the field effect tube to reach the frequency of the ultrasonic wave, and then converted into a high frequency mechanical oscillation by the transducer and transmitted to the cleaning solvent. The cleaning liquid radiates forward in alternating density, causing the liquid to vibrate and generate countless tiny bubbles. These bubbles form and grow in the negative pressure zone where the ultrasonic waves propagate longitudinally, and quickly close in the positive pressure zone, forming a "cavitation effect". The microbubbles in the liquid vibrate under the action of the sound field. When the sound pressure reaches a certain value, the bubbles grow rapidly and then close suddenly. When the bubbles close, a shock wave is generated, and thousands of atmospheric pressures are generated around, thereby destroying the insoluble dirt. and disperse them in the solution.

1.2 The working principle of the ozone generator

The all-in-one machine uses a high-voltage discharge ozone disinfection machine, which uses a certain frequency of high-voltage current to create a high-voltage corona electric field, so that oxygen molecules in or around the electric field undergo electrochemical reactions to produce ozone .

1.3 Bluetooth control module

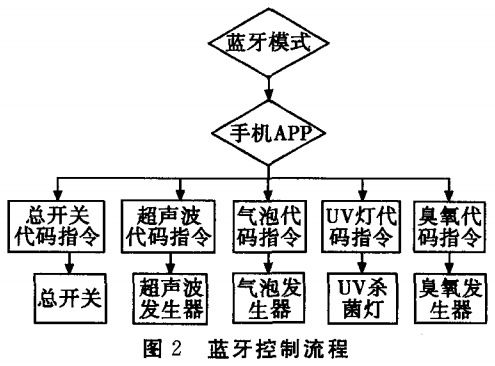

The Bluetooth control process is shown in Figure 2. The wireless control mobile phone APP is connected to the Bluetooth receiving module of the intelligent controller through Bluetooth, controlled through the serial communication program, and the sensor data acquisition program collects the signals of various sensors. The relay control program controls the opening or closing of the relay according to the control command of Bluetooth, and realizes the cleaning and disinfection work of the dishwasher by controlling the power switch of each working element.

2. The main structure of the portable cleaning and disinfecting machine

The all-in-one machine is composed of five parts: intelligent control module, manual control module, timing device, cleaning device, and disinfection and sterilization device. Among them, the intelligent control module is composed of a Bluetooth receiving module, a signal processor and a relay; the manual control module is mainly composed of a jog switch; the timing device is a time relay; the cleaning device is composed of an ultrasonic generator, a transducer and an air pump; The sterilizing device is composed of an ozone generator and a UV sterilizing lamp.

The portable cleaning and disinfection all-in-one machine has complete functions and is easy to carry. There are the following functional advantages.

(1) Ultrasonic cleaning is fast, high-quality, water-saving, power-saving, sterilizing, reducing the use of cleaning agents, and can be automated. The combination of Bluetooth intelligent control and manual panel control realizes the mutual conversion between wireless control and manual control. Adopt more advanced uv/o. The water treatment system disinfects the cleaning water to effectively sterilize and disinfect without DBPS residue.

(2) Compared with traditional dishwashers, this portable cleaning and disinfection machine has complete functions. Traditional dishwashers are fixed in the home kitchen, have a single function, consume time and electricity, and require a large amount of detergent. The machine is not only easy to carry and combines the principle of ultrasonic and bubble impact, the cleaning effect is better, and there is also a (uv/O3) system for sterilization.

(3) There is no easy-to-carry dishwasher on the market at present. The generation of this portable cleaning and disinfection all-in-one machine will solve the troubles of people's outdoor life, bring great convenience to family life, and have a good market prospect.

3. Scheme design of ultraviolet disinfection machine

In the field of facility agriculture in my country, after the soil has been continuously cultivated for 3 years, viruses and secondary salinization will lead to drastic destruction of the cultivated soil environment, disorder of the ecosystem, and serious harm caused by excessive application of drugs and fertilizers. The periodicity of traditional cultivation has given birth to the rise of soilless cultivation, which can effectively deal with the deterioration of the ecosystem and the reduction of vegetable quality.

With the increase of population, the reduction of arable land and the increase of labor cost, my country's agricultural planting mode is gradually changing to the soilless cultivation mode, both technically and economically, and the cultivation method of greenhouse plants is gradually changing to nutrient solution cultivation. Due to the complex working conditions and environment of the planting industry, considering the composition of the cost of the planting industry, the nutrient solution is mostly recycled, which leads to the emergence of a large number of bacteria, which is easy to cause diseases to plants, greatly affects the planting effect and crop quality, and also wastes The active ingredients of the nutrient solution.

At present, the developed agricultural countries in the world have developed a new solution in the field of irrigation disinfection, that is, ultraviolet disinfection technology, and have given birth to mature disinfection equipment. In my country, the development of soilless cultivation has not yet reached the level of advanced agricultural countries, and pesticide disinfection is still being used. The main problems of chemical agent antivirus exist: 1. a single agent only plays a killing effect on a certain pathogen; 2. the medicament dissolved in the nutrient solution is easy to be absorbed by the plant and remains in the plant body. Chemical disinfection is neither safe nor efficient enough. In comparison, ultraviolet disinfection is more reasonable.

In the greenhouse soilless cultivation process system, in order to ensure the healthy growth of crops and the safety of ingredients, the most critical issue is to ensure the effectiveness of the nutrient solution. Since the planting industry itself is very sensitive to costs, how to use nutrient solution economically, rationally and greenly to ensure the competitiveness of enterprises on the basis of ensuring crop quality is a concern of scholars in related fields. Agricultural powers such as the Netherlands have generally recognized the way of nutrient solution recycling. On the one hand, it is based on economic considerations, and at the same time, its waste liquid treatment technology has met the actual use requirements. In the entire process chain of nutrient solution recycling, disinfection is the most critical link, which has important research prospects and significance.

In order to solve the problem of nutrient solution reuse and develop operation equipment suitable for our country's agriculture, the author has developed a circulating irrigation ultraviolet sterilizer, trying to fill the domestic gap in this field.

4.The working principle of ultraviolet disinfection machine

4.1 Introduction of UV Disinfection Mechanism

The agricultural sterilizer is mainly used for the recycling of nutrient solutions in planting systems such as tidal irrigation, drip irrigation and hydroponics. Experiments have proved that if the pathogen infection is allowed to spread, it will cause disaster to the crops in the entire cultivation group. Therefore, in the process of recycling nutrient solution, the disinfection link is very important.

In the research in related fields, researchers from various countries have conducted practical investigations on various disinfection methods, and some representative methods are listed below.

1) Ozone disinfection. This solution applies ozone to the nutrient solution for disinfection, and its disinfection effect is remarkable; but the side effect of this solution is that it will react with the active ingredients in the nutrient solution and reduce the nutrient ratio of the nutrient solution.

2) Electrothermal disinfection. This solution needs to increase the temperature of the nutrient solution to achieve the purpose of sterilization; but its cost is very high, and the sterilization cycle is longer.

3) Advanced oxidation disinfection. The technical requirements of this scheme are not high, but the use of this method will lead to the accumulation of chemicals in the roots of the product, resulting in safety problems.

4) Sterilized by ultra-fine filtration. It has a wide range of applications in sewage treatment, but the high investment amount of its equipment is not suitable for use in the agricultural field.

At present, the ultraviolet radiation disinfection method is an ideal application method in terms of investment and working principle: ① This method can effectively kill relevant bacteria; ② It has little effect on the active ingredients in the nutrient solution; ③ The equipment investment amount can be large Accepted by most companies.

The principle of ultraviolet disinfection is very simple. All microorganisms will be affected by fluctuations of specific wavelengths, which is the essential property of living things, so all microorganisms have their own "nemesis", as long as they are exposed to radiation of specific wavelengths, they will die within a sufficient time. The research equipment utilizes a specific wavelength (254nm) of ultraviolet light. According to the actual needs and working conditions of the enterprise, the system is customized to maintain the disinfection efficiency and time, and to kill harmful microorganisms while keeping the characteristics of the nutrient solution unchanged, and to ensure that the enterprise The flow rate used for the nutrient solution.

According to the data provided by Wageningen University in the Netherlands, when the nutrient solution is sterilized, when the ultraviolet radiation intensity reaches 100mJ/cm2, it can effectively kill bacteria, nematodes and yeasts; when the ultraviolet radiation intensity reaches 150mJ/cm2, it can Effectively kill fungi, Fusarium and Phytophthora; when the ultraviolet radiation intensity reaches 250mJ/cm2, it can effectively kill viruses and cucumber mosaic bacteria.

4.2 Design idea of ultraviolet sterilizer scheme

The disinfection machine can effectively eliminate the potential danger of microorganisms in the nutrient solution to crops. The design process of this ultraviolet disinfection equipment focuses on the design concept of object-oriented, reliable and durable, which is suitable for large, medium and small planting enterprises, especially for tidal irrigation. The initial design of the ultraviolet disinfection equipment, according to different user needs, the key parameters of the initial design considerations are: ① radiation amount; ② light penetration rate.

According to this line of thinking, the disinfection machine has 3 alternative radiation devices in the design (customization) stage to achieve a penetration rate of 10% or higher. The independent modular design of the radiation room enables the ultraviolet disinfection equipment to be customized parametrically to meet the needs of different planting operations, and its compatibility is more complete. Through the precise regulation of the radiation dose, the equipment avoids affecting the nutrient ratio of the nutrient solution itself as much as possible, and avoids blindly destroying the ecological balance of the working condition, so that the entire irrigation system has good stability; at the same time, it also reduces the probability of supplementing chemicals. To some extent, it also saves the process cost of the enterprise. Penetration rate is an important index to measure the degree of pollution of fertilizer and water. It refers to the ratio of the illuminance measured before and after the ultraviolet (ray) light passes through a 1 cm3 water sample. The larger the ratio, the clearer the water, and the higher the turbidity of the water.

Due to the complex agricultural working environment and the diversity of domestic planting users, the parameter customization of the equipment itself depends on the iron chelate in the local water body, organic particles (from peat or decomposed organic matter in the cocoa planting substrate), ecological It is a complex optimization problem due to various factors such as population distribution, impurity types, water quality characteristics and fertilization schemes.

Before users consider choosing ultraviolet disinfection equipment, they should make statistics on their own construction foundation, and provide information such as the overall irrigation plan, water quality data, nutrient ratio, application plan and product type of the company, and the selection will be assisted by professional engineers; when the factory produces When the target changes, the corresponding disinfection equipment also needs to be adjusted accordingly in the customization stage.

According to the different penetration rates, the design and structure of the low-pressure ultraviolet disinfection equipment provides three kinds of radiation lamp chambers to achieve the appropriate disinfection effect: when the UV light penetration rate is > 45%, the return water flows through the radiation chamber, and the ultraviolet light can penetrate quite a lot. Large-thickness water body; when the penetration rate ranges from 25% to 45%, the return water flows through the radiation chamber, and ultraviolet light can penetrate medium-thickness water bodies; when the penetration rate is less than 25%, the liquid is already turbid enough, and the light transmission is very poor , so in this case, it is necessary to adjust the structure of the radiation chamber to reduce the annular cross-sectional area, and at the same time consider reducing the flow rate.

When the penetration rate is the same (similar), the sterilization rate and the cross-sectional area of the radiation chamber have a similar inverse relationship. The ultraviolet lamp tube is located in the center of the radiation chamber, and its light density decreases sequentially from the inside to the outside. For example, given the flow rate or the effective time of the nutrient solution passing through the radiation chamber, the optional range of the diameter of the radiation chamber can be obtained through calculation, and the corresponding use cost can be obtained. The user can select parameters according to the specific use requirements to achieve effective sterilization while taking into account the cost. Effect.

Customized disinfection equipment itself can be regarded as an expert decision-making system. In principle, water quality parameters, crop varieties, irrigation schemes, etc. under enterprise working conditions are all inputs into a design black box, and the disinfection rate and cost are used as design constraints. The research intends to gradually optimize the intelligence of the disinfection machine, enrich its parametric design function, enhance its compatibility, and strive to improve market adaptability.

4.3 Disinfection machine operating logic

In principle, in addition to the disinfection function, the disinfection machine mainly realizes the following functions: 1) Control the flow of nutrient solution. Regardless of the pure disinfection properties, the entire operating cycle of the equipment needs to continuously and real-time measure the ultraviolet radiation intensity, and then control the time for the fluid to pass through the ultraviolet disinfection machine according to the target radiation value. The adjustable electric valve is used in the ultraviolet radiation room, and the water flow is controlled to match the current radiation value through program calculation. The degree of contamination of the nutrient solution determines the reading of the UV radiation sensor. The more polluted the recovered nutrient solution, the lower the reading of the ultraviolet radiation value, and the longer the nutrient solution stays in the ultraviolet radiation chamber, so as to achieve the purpose of disinfection. Strict water flow control can ensure that the recovered nutrient solution is completely sterilized.

2) Ultraviolet disinfection lamp monitoring/alarm. The UV sterilizer system continuously monitors the lamps for proper operation. If some of the UV lamps are not working properly, the system will send out an alarm immediately. At the same time, when the lamp reaches the preset working upper limit, the machine will also remind the user to replace the consumables.

3) Clean the UV radiation chamber. Due to the high pH value of the recovered nutrient solution, such as iron ions and calcium ions in the fertilizer in the water will be deposited on the tube wall of the ultraviolet radiation chamber to varying degrees. Deposits affect the radiation intensity of the UV lamp. The system uses nitric acid to clean the radiation chamber, and periodically lowers the pH in the system to keep the radiation chamber clean. The entire cleaning process is controlled and operated by algorithms without human intervention. The computer will start the cleaning command according to the measured radiation intensity and the working hours of the ultraviolet lamp. When the cleaning process is running, the disinfection process will be interrupted, and the radiation chamber will be injected with high-concentration nitric acid (pH=3.5). After staying in the radiation chamber for about 10 minutes, it will be driven back into the drainage tank by the acid pump.

4) Pre-filter set. It is mainly used to filter and recover large particles of dirt carried by nutrient solution. The dust particles in the nutrient solution will cause shadows in the radiation chamber, and at the same time cause the germs hidden in the micropores of the solid particles to pass through the ultraviolet radiation chamber without being killed. Therefore, a pre-filtration device must be equipped to remove particles above 30 μm from the recovered nutrient solution. The automatic ultraviolet disinfection machine is equipped with pre-filtration equipment, including a set of sand filter and a set of laminated filter.

5. Design and development process of ultraviolet disinfection machine

5.1 Main components of the disinfection machine system

The key equipment used in the whole system is: ultraviolet disinfection lamp (including quartz tube, mounting bracket), sand filter, laminated filter, system pump, acid metering pump, control cabinet and expansion tank. The main measuring equipment/sensors used are: EC sensor, pH sensor, liquid level sensor (acid/liquid), radiation intensity sensor, impeller flowmeter, visual flowmeter and pressure gauge, etc.

According to the diversity and complexity of the environment in which the sterilizer is used, and considering the overall production cost, the main equipment is connected by PVC pipes, and the electric control part is equipped with a special cabinet and a protective shell.

5.2 Workflow of UV disinfection machine

1) Preheating: Turn on the system pump, and turn on the ultraviolet disinfection lamp when the system is full of water. Monitor the value of the radiation intensity sensor. Before the preset target is reached, the recovered nutrient solution must not enter the disinfection water tank and be re-discharged into the drainage tank until the ultraviolet lamp is preheated to the set radiation intensity. This process takes about 10 minutes.

2) Disinfection: After the preheating is over, the disinfection machine enters the normal working state, and the system pump sends the recovered nutrient solution in the drainage tank to the pre-filter group for preliminary filtration and then into the ultraviolet radiation room for disinfection. The sterilized nutrient solution is sent to the disinfection water tank for the next irrigation. If the liquid level in the drainage tank is too low or the liquid level in the disinfection water tank is too high, the disinfection machine will automatically stop.

3) Backwashing: The gravel filter can be backwashed automatically. When the value of the differential pressure sensor on the sand filter increases, the program controls the sand filter to backwash.

4) Pickling: The computer will start the process according to the measured radiation intensity or the working hours of the ultraviolet lamp.

5.3 The operation control system of the disinfection machine

In terms of equipment control, the whole system is divided into five parts: parameter setting, automatic operation, manual operation, I/O monitoring and data reporting.

1) Parameter setting. This part includes warm-up time, pickling UV value, acid stay time in the disinfection room, UV lamp replacement time, acid pump automatic flow rate percentage, valve switch overtime, sand tank cleaning time, sand tank cleaning interval time, flow sensor control Device, water flow rate and other settings.

2) Manual operation. This interface can manually operate all valves, open or close them, and monitor the valve switch status at the same time. The following is explained by taking the drain valve VR as an example.

Button "OFF/ON": Press this button, and the VR valve will switch between closing/opening. When the display is OFF, the indicator light "OFF" will light up. Press this button, the VR valve will open, and the button will display "ON" at the same time ; After 3 s, when the valve is fully opened, the indicator light "ON" is on.

The acid pump is operated in 3 parts, turn on the power of the acid pump, enter the flow rate percentage (percentage of 100L/h), and finally turn on the remote control switch. The panel can also manually control the drain valve, disinfection valve, gravel selection valve, filter valve, pickling selection valve, pickling valve UV lamp (switch), water pump, disinfection, and preheating, and display relevant status information .

3) Automatic operation. In the automatic operation interface, press "Disinfection OFF" to enter the automatic disinfection mode, this key is displayed as "Disinfection OFF", and the top of the interface displays disinfection, then press to stop disinfection; press "Pickling OFF" to enter the automatic pickling mode , this key is displayed as "pickling OFF", and the top of the interface displays pickling, press it again to stop pickling.

Summarize

In this paper, an ultraviolet nutrient solution disinfection machine is designed and trial-manufactured, which mainly includes ultraviolet disinfection lamps, gravel filters, laminated filters, system pumps, acid pumps, PVC pipelines and automatic control equipment. Under the existing test conditions, the sterilization rate of the ultraviolet disinfection machine is maintained between 92% and 95%. In order to improve the sterilization rate and stabilize the deviation range, the next step is to further optimize the design of the structure of the ultraviolet disinfection chamber and the overall flow/velocity control algorithm of the equipment to achieve a higher actual sterilization effect.

This prototype is an attempt to sterilize the field of nutrient solution circulation irrigation in China. It aims to fill the gap in the domestic market in this field, and strive to make the equipment cost affordable to domestic planting enterprises on the basis of reaching the disinfection level of similar foreign products. The research and development equipment of the subject is dedicated to improving the utilization efficiency of nutrient solution, optimizing crop quality, improving the hygiene and safety of planting enterprises, and reducing enterprise investment costs and market risks.

The above are the details of the portable disinfection machine solution introduced by Shenzhen Zuchuang Microelectronics Co., Ltd. for you. If you have the development and design needs of ultraviolet disinfection equipment, you can rest assured to entrust it to us. We have rich experience in customized development of electronic products, and can evaluate the development cycle and IC price as soon as possible, and can also calculate the PCBA quotation. We are a number of chip agents at home and abroad: Songhan, Yingguang, Jieli, Ankai, Quanzhi, realtek, with MCU, voice IC, Bluetooth IC and module, wifi module. Our development capabilities cover PCB design, single-chip microcomputer development, Bluetooth technology development, software customization development, APP customization development, WeChat official account development and other hardware and software design. It can also undertake the research and development of smart electronic products, the design of household appliances, the development of beauty equipment, the development of Internet of Things applications, the design of smart home solutions, the development of TWS earphones, the development of Bluetooth earphone speakers, the development of children's toys, and the development of electronic education products.

- TOP