- Home >> Solution >> Appliances >> cookers

Cooking machine solution

The cooking machine is developed on the basis of the juicer. In addition to the basic functions of squeezing juice and making soy milk, it can also make meat stuffing, make shaved ice and jam. At present, there are many types of food processors on the market, and the functional scope of each machine is also uneven. In the process of using the cooking machine, there are also many problems, such as motor heating, stirring blade failure and difficulty in cleaning. The cooking machine is a small household appliance, which is fast and convenient to use, and is deeply loved by consumers. Therefore, the design and research of the household fruit and vegetable cooking machine is currently a research hotspot in small household appliances such as juicers and cooking machines.

1. Functional characteristics of cooking machine

1. The practicality of the cooking machine

Due to different age groups, family members have different nutritional needs, and at the same time, personal taste preferences are also different. Household fruit and vegetable cooking machines need to have more comprehensive practicability in order to process fruits and vegetables for these groups.

2. The safety of the cooking machine

The safety of household fruit and vegetable cooking machines includes operational safety and environmental and healthy food safety. Operational safety is mainly the safety of the machine and the operator during use, such as whether there is leakage during use, whether it is overheated during high-speed rotation, and whether it is harmful to the operator. Food safety refers to food contact safety. Since the juice is squeezed out by the fruit and vegetable cooking machine, consumers have to eat it directly. When the ingredients are processed, they are in direct contact with the inner wall of the cooking machine and the knives. Therefore, the material of the cooking machine must meet certain food safety requirements. , if the material can be in direct contact with food, it will not cause chemical changes of harmful components in the human body or precipitate harmful substances, and will not have any impact on the taste of food, so as to ensure food safety.

3. Green and healthy cooking machine

Green Design (Green Design), its connotation is to fully consider the impact of the produced products on resources and the environment throughout the life cycle of the product, and integrate the recyclability, reusability, disassembly and maintainability of the product On the basis of setting environmental attributes as design goals and paying attention to them, ensure that the quality, function, development cycle and service life of products meet the relevant requirements, and design products to minimize environmental pollution and minimize energy consumption. Minimized, parts and products can be reused and recycled. The green design in the fruit and vegetable juicer is reflected in the following three aspects.

(1) Power system. Traditional food machinery is powered by a hydraulic system, which has problems such as noise pollution and oil leakage pollution, and even affects the quality of food. Under the guidance of green design, electricity is used instead of petroleum as power, and new energy sources such as vegetable oil, solar energy and natural gas are developed as power.

(2) In terms of machine material selection. Under the advocacy of green design, choose low-energy, low-pollution, low-cost, easy-to-process, easy-to-handle and easy-to-recycle materials that are corrosion-resistant, non-toxic, and easy to disassemble and clean, because the food produced by the fruit and vegetable juicer is for consumers to directly Food quality is related to the health of consumers, so the selection of materials should be green.

(3) Structural design. Adhere to the concept of green to make it easy to assemble, manufacture and disassemble. On the premise of ensuring quality, reduce the number of parts used as much as possible, and achieve clean production and reduce environmental pollution as much as possible in the assembly and manufacturing process. Lifespan etc.

4. The cooking machine improves the nutritional content

Cell wall breaking technology is the method of breaking the bacterial cell wall by using enzymatic method, chemical method, physical method or several methods in combination. Taking plant cells as an example, the cell wall is divided into three layers, namely the intercellular layer (middle layer), primary wall and secondary wall. Such layers of thick walls impermeable to moisture and nutrients. Cell wall breaking technology is a technology that breaks plant cell walls to allow water and nutrients to be better absorbed and maintain active ingredients, release phytochemicals, and maximize the integration of dietary fiber, vitamins and other nutrients.

Taking the food cooking machine as an example, the "wall-breaking technology" cooking machine thoroughly grinds the food to extremely fine in just a few tens of seconds through a reasonably customized ultra-high speed. The cell wall releases phytochemicals and maximizes the integration of dietary fiber, vitamins and other nutrients in fruits and vegetables. The ingredients processed by the cooking machine with wall-breaking technology can increase the nutritional content by 3 to 4 times and are easier to absorb.

2. Design scheme of household fruit and vegetable cooking machine

Household fruit and vegetable cooking machines aim at freshly squeezed seasonal fruits and vegetables, and mainly squeeze and break the walls of fruits and vegetables. The fruit and vegetable juicer is divided into 3 parts: the motor of the power source is the prime mover part, the transmission part that provides different speeds and the cutting and stirring part that performs the juicing operation. Its working principle brings power to the motor conversion, the speed change device meets the requirements of juicing at different speeds, and different cutting tools or mixing and stirring devices are used to bring different fruit and vegetable cooking effects. Set the speed adjustment gear according to the different usage conditions to meet the juicing needs of different fruits and vegetables. With the green design as the running through, with the goal of convenience, safety and reliability, combined with the nutritional technology of fruit and vegetable wall breaking, the main structure of the household fruit and vegetable juicer is designed.

(1) Diverse cooking functions. According to the different characteristics of fruits and vegetables, according to nutrition and convenient cooking methods, the fruit and vegetable cooking machine provides a variety of fruit and vegetable cooking gears. There are ordinary stirring gears, succulent fruit and vegetable gears, general fruit and vegetable gears, broken fruit and vegetable gears and other gears reserved for juicing. Among them, the ordinary stirring gear can provide juice mixing. Broken fruit and vegetable is a physical method combined with fruit and vegetable wall breaking technology to break the wall of fruit and vegetable and release better nutrients.

(2) Detachable design for easy cleaning. In the use of fruit and vegetable cooking machines, the machine needs to be thoroughly cleaned. Whether the cleaning of the fruit and vegetable cooking machine is perfect will affect its use effect. In view of the fact that the cooking machine is difficult to clean after use, first of all, it is necessary to choose food-grade and easy-to-clean materials for the material selection of the cooking machine. In addition, in terms of structural design, it adopts a detachable structure, which is easy to rinse and clean.

(3) Diversification of cutting tools. According to the diversity of fruit and vegetable processing varieties, different knives are added to make the cooking machine meet the functions of mixing, juicing and wall breaking of commonly used fruits and vegetables. In addition, different fruits and vegetables are treated with different knives, which also fundamentally prolongs the service life of the knives.

3. The design idea of cooking machine

The cooking machine uses a single-chip microcomputer as the control core, combined with anti-overflow and anti-dry overflow inspection circuits, temperature detection modules, power supply circuits, heating drive circuit modules, alarm modules, and motor drive modules, which can complete the production of various freshly squeezed drinks.

In this system, the voltage stabilizing circuit provides the voltage required by the system for different peripherals in the whole system. The single-chip microcomputer needs to detect the input of the button circuit, temperature detection circuit, anti-overflow and anti-dry circuit, and at the same time control the heating circuit and alarm circuit. , stepper motor circuit and display circuit these modules. The heating circuit is used to generate heat to heat the mixture of water and various grains or dried fruits; the temperature detection circuit is used to detect the temperature of the drink, and the temperature data is used for the MCU to make decisions on the entire system; the anti-overflow and anti-dry circuit is used to Detect the water level of the system to ensure the safe and reliable operation of the system; the key circuit is used as the input of the user, and the alarm circuit is used as the alarm and prompt when the system is abnormal; the stepper motor is used as the power equipment of beating to realize the function of crushing materials; the display circuit is used as a human machine Use interactively to display the working mode, liquid level status and liquid temperature, and other related slurry status.

1. Anti-spill and anti-dry module circuit design

Since the cooking machine may overflow, dry-burn, etc. during the working process, in this case, if the machine continues to work, there will be a great safety hazard, and a fire may occur in severe cases. Therefore, it is necessary to monitor the water level of the cooking machine. The role of the water level monitoring and overflow circuit is to use the sensor as an information collection system to control the problems of dry burning and boiling overflow when the cooking machine is short of water.

The water level and temperature detection circuit uses a probe analog sensor to detect the water level and boiling overflow, and then outputs high and low levels through the comparator, so that the water level and the overflow state during boiling can be detected by the single-chip microcomputer to detect the level of the comparator output level ; When S1 is closed, a high-level signal is given to the microcontroller, indicating that the soybean milk overflows, and when the switch is turned on, it indicates that there is no overflow. Similarly, when S2 is closed, the input high level means dry heating, and when the switch is turned on, it means normal. When any of the buttons is closed, it will cause a buzzer alarm, indicating that the power can be turned off.

2. Design of heating module and refining module

The function of the heating circuit is to cook the ingredients that are ground into powder through the heating tube. The heater power used in this design is 800w. The function of the refining circuit is to mix the ingredients into powder through the motor. Due to the high speed of the motor, in order to avoid damage caused by its continuous operation, this design adopts the intermittent beating method. The working principle of the heating circuit is that the single-chip microcomputer sends out a signal, amplifies the signal through the transistor Q2, and then starts the relay RL1, and the relay RL1 absorbs the patch after obtaining the current, thereby forming a heating current circuit, and the heating circuit starts to work. The working principle of the beating circuit is that the single-chip microcomputer sends a signal to amplify the signal through the transistor Q3, and then starts the relay RL2, and the relay RL2 absorbs the iron sheet after receiving the current, thereby forming a beating current circuit, and making the beating circuit start to work.

3. Power module design

The power module is composed of a power transformer, a rectifier circuit, a filter circuit, and a voltage stabilizing circuit. Among them, the power transformer TR1 converts the 220V AC voltage provided by the grid into the AC voltage required by various circuit devices; the rectifier circuit performs bridge rectification on the secondary output AC, and is filtered by the filter capacitor and input to the 7812 voltage regulator chip Go, the voltage from the 7812 is 12V DC after passing through the filter capacitor, and the voltage is supplied to the stepper motor and the heating circuit. At the same time, the voltage is input to the three-terminal voltage regulator 7805, and then filtered to obtain a 5V DC power supply , the voltage is supplied to peripherals such as MCU and anti-dry circuit.

The alarm module is composed of a transistor Q1, a resistor R5 and a buzzer LS1. The working process of the alarm module circuit is that when the cooking machine is finished or the water level detection does not meet the standard, the microcontroller will send a signal to the P1. Zoom in and finally make the buzzer alarm to give a notification.

During the cooking process of the cooking machine, due to the high temperature, the acidic substances in the drink will generate a lot of foam, which will affect the normal cooking work. In order not to stop working and save a lot of time, an active defoaming device is needed. Press and hang two metal rods on the main shaft of the motor. The metal rods are made of copper metal material, which has excellent electrical conductivity, and the data under many tests shows that the metal rods are installed 2.5 cm below the anti-overflow electrode. The defoaming effect is the best, so the design of the active defoaming device is completed.

4. Design of cooking machine control program

1. The main program design of cooking machine

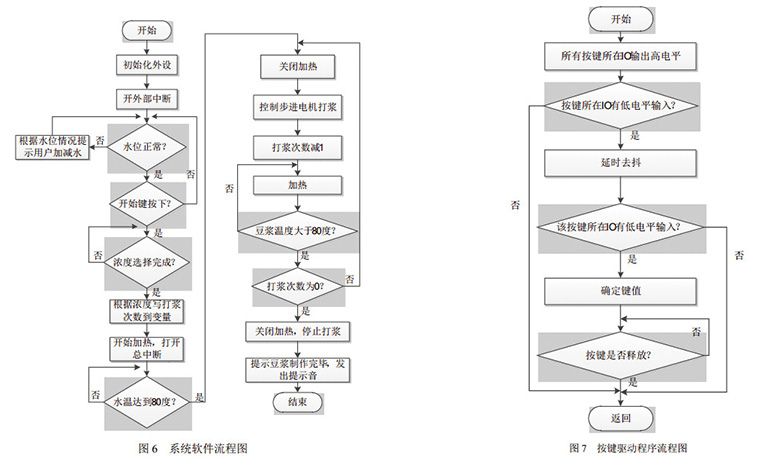

The main program of the cooking machine is the control and decision maker of the entire system workflow. It mainly controls the output of the stepper motor, heater, display screen and buzzer by detecting the input of the water level sensor and temperature sensor, so as to achieve the goal of making the entire system The purpose of orderly operation. The flow chart of the main program is shown in Figure 6, taking soybean milk as an example.

It can be seen from the flowchart that after the system is powered on, the relevant peripherals are first initialized, and these peripherals include buzzers, LCD displays, heaters, temperature sensors, etc. After the initialization of peripherals is completed, external interrupt 0 and external interrupt 1 need to be turned on, which is a necessary condition for detecting drink overflow and dry boiling. After that, the system will detect the abnormality of the water level. If the system detects that the water level is too high or too low, the LCD will prompt the user to add water or reduce the water to make the water level reach the normal level; if the water level is normal, the system will detect whether the user presses the start button, so that The purpose is to allow the user to confirm the water added to the soymilk machine. After the user presses the start button, the system will detect whether the user has selected the concentration of the drink to be made through the button; after the concentration is selected, the system will According to the concentration of the drink selected by the user, set a number of beating times and write the number of times into the variable, and then start heating the water to 80 degrees; after the water temperature reaches 80 degrees, the system will turn off the heating and start to control the forward and reverse rotation of the stepping motor To drive the blade to beating. After the specified number of beating cycles, the system will heat the water temperature to 80 degrees again. After that, the beating frequency variable will be reduced by 1, and then the heating will be turned off. Continue beating and heating, and the variable value will be reduced by 1.... Repeat this until the beating frequency variable When it is reduced to 0, it means that the soybean milk is finished. After that, the system turns off the beating and heating, and then the LCD shows that the beating is completed, and the buzzer sounds.

2. Button drive design of cooking machine

In this design, the buttons are used to obtain the user's input, mainly for the confirmation of the user's water level and the selection of the soybean milk making mode. This design uses independent keys, and its programming is relatively simple. The program flow chart is shown in Figure 7.

It can be seen from the figure that the most important part of the button detection function is debounce. This is because if a button is pressed, the ideal situation is to jump directly from high level to low level, but because the human hand is pressing the button There will be jitter during the process, or due to the characteristics of the button itself, there will be more or less jitter in the process of pressing it, so that there will be a lot of jitter in the entire level when the button is pressed. Therefore, if the vibration is not removed, the detected state of the button will be incorrect, resulting in misoperation. Under normal circumstances, it takes about 5~10ms for the button to be stable when it is pressed at the beginning, and the debounce delay added by this system is 5ms.

Summarize

This paper fully analyzes the market demand target of household fruit and vegetable cooking machines based on the market demand and use functions of fruit and vegetable cooking machines. Combining various design methods and ideas, aiming at practicality, safety, greenness and nutrition, a small household fruit and vegetable cooking machine that can obtain fruit juice conveniently and quickly, is easy to clean and safe to use is designed. In the main structure of the fruit and vegetable cooking machine, a gear design with diversified cooking functions is added, a partially detachable structural design is adopted for the convenience of cleaning, and the knives used for cooking fruits and vegetables are diversified, reaching the level of a household fruit and vegetable cooking machine. purpose of use.

This paper introduces the principle and system software and hardware design of a fully automatic cooking machine based on single-chip microcomputer. The system uses single-chip microcomputer as the core controller, uses the principle of electric heating and sound and light alarm systems, and can realize water temperature heating, drink grinding, automatic alarm, etc. Function and good human-computer interaction interface, easy to use, good stability, low power consumption and so on.

The above are the details of the design of the home cooking machine introduced by Shenzhen Zuchuang Microelectronics Co., Ltd. for you. If you have electronic function development needs for fruit and vegetable machines, you can trust us. We have rich experience in customized development of electronic products. We can evaluate the development cycle and IC price as soon as possible, and can also calculate PCBA quotations. We are a number of chip agents at home and abroad, including MCU, voice IC, Bluetooth IC and modules, wifi modules. Our development capabilities cover PCB design, single-chip microcomputer development, software custom development, APP custom development, WeChat official account development and other hardware and software design. It can also undertake the research and development of smart electronic products, household appliances scheme design, beauty equipment development, Internet of Things application development, smart home scheme design, TWS scheme development, Bluetooth audio development, children's toy scheme development, and electronic education product development.

- TOP