- Home >> Solution >> Appliances >> cookers

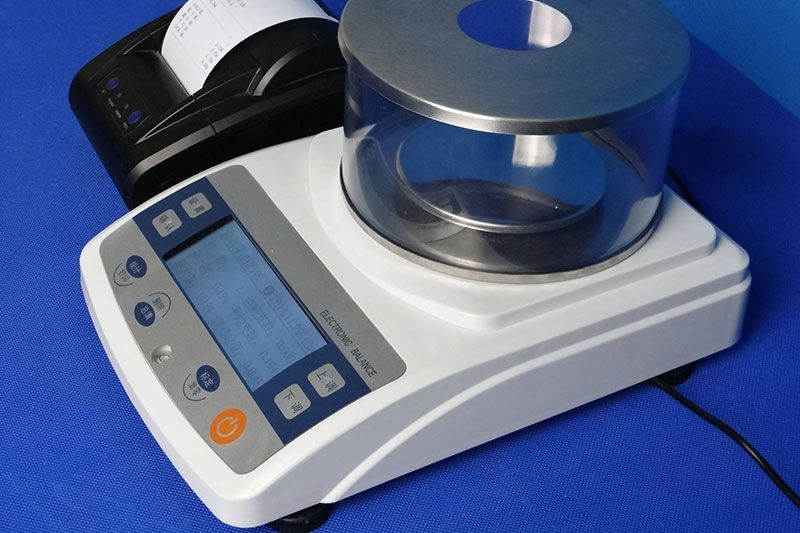

Electronic scale solution

Electronic scales are weighing instruments used for weighing, and their applications range from trading markets, enterprises, factories and mines, to every family unit, which can be seen everywhere. Among them, the subdivisions for household use include kitchen scales, weight scales, and body fat scales. The electronic scale is mainly a tool for measuring the mass of an object by using the lever balance principle of force and Hooke's law. Under the action of the gravity of the object, the elastic body deforms to measure the value of gravity. The electronic scale mainly consists of a load cell, a weighing platform, a weighing indicator, a shielded signal cable, and a junction box.

1. The principle of the electronic scale

1. The operating principle of the electronic scale

The weighing instrument detection system of the electronic scale is mainly composed of: sensor amplification circuit, data acquisition (analog/digital conversion) circuit, central processing unit, feedback zero adjustment circuit, external communication and power supply support, etc. The function of the sensor amplification detection circuit It is to convert the weight signal into a micro-variable voltage signal through the strain gauge sensor, and amplify it to the voltage signal suitable for the analog/digital conversion chip to perform A/D conversion. The system error of the instrument is mainly generated in this part, so the design relationship of this part is the accuracy of the whole system. The central processing unit is responsible for the operation control of the entire system, and performs data processing, automatic calibration, automatic range conversion, adaptive sensor replacement, and finally transmits the data to be displayed to the human-machine interface system. External communication refers to the circuit power supply system that transmits instructions and data between the CPU of the detection system and the CPU of the man-machine interface system. The power supply system provides a good power supply system for the stable operation of the system, and provides high-precision bridge power supply.

2. The weighing process of the electronic scale

First, put the weighed object on the weighing platform, the weighing platform will produce elastic changes due to the action of gravity, and the sensor elastic body that undergoes elastic changes will generate excitation voltage, and the generated voltage value is proportional to the weight of the object A certain ratio, which is converted into a digital signal through the amplifying circuit and displayed on the weighing display.

2.The main structural components of the electronic scale

1. Load cell

Electronic scales usually use resistance strain load cells, and the structure is relatively simple, the technology tends to be mature, and the manufacture is simple, with the advantages of high accuracy and low price. Electronic scales (except for large electronic truck scales) usually use four load cells, and they are connected in parallel. Because multiple load cells are used, the output electrical impedance, sensitivity and other data of each load cell will vary. There are discrepancies that lead to errors in weighing results. Therefore, in order to solve this problem, the output terminal of each sensor can be connected to the junction box device, and the output can be obtained.

2. Sensor junction box

The sensor junction box can bring together the wiring of all sensors. The main structure is a passive resistance network. Each load cell is equipped with one or two adjustable resistances and is connected in parallel with the sensor. When adjusting a resistance of the junction box, the output impedance of the sensor will be changed, so that the output impedance of all the sensors in the electronic scale can be consistent and meet the standard.

3. Weighing display instrument

The weighing display instrument of the electronic scale is the so-called meter head, which is used to provide users with electronic scale information and is also the centralized position of the electronic scale function. The working process is that the power supply in the meter supplies power to the load cell through the power line in the main line. When there is an object, the elastic body of the sensor changes, and the organization of the resistance strain gauge adsorbed on the elastic body will change. This is The sensor will get an electrical signal proportional to the weight value.

Another function of the meter is to allow the user to communicate with the meter. The user can use the numbers on the meter to input relevant information, and the meter can do the work of weighing, calculating prices, etc., and play the function of the electronic scale. . And because the weighing result is a screen number, the accuracy is higher, and there will be no easy misreading of the pointer scale.

3. Hardware Design Scheme of Smart Electronic Scale

The smart electronic scale is composed of a data acquisition module, a data processing module, a key processing module, an overweight alarm module, a display module and a main controller module. Among them: the data acquisition module is composed of resistance strain gauges, elastic devices, resistors and shells. The data processing module amplifies the signal in the data acquisition module and realizes A/D conversion, and then transmits the processed signal to the single-chip microcomputer, and then makes a corresponding display on the display screen.

1. Data acquisition module

The selection of sensors is the core issue of intelligent electronic scales. The load-bearing system composed of sensors requires strong environmental adaptability, and at the same time, the accuracy and sensitivity must meet the design requirements. Considering comprehensively, the sensor of this intelligent electronic scale uses a resistive strain gauge. The data acquisition module of the intelligent electronic scale includes a resistance strain gauge, an elastic device, a resistor and a shell.

2. Data processing module

The data processing module needs to amplify the collected signal and complete the analog-to-digital conversion at the same time. In the case of satisfying the data processing function, the simpler the circuit hardware design, the better. Based on such considerations, the smart electronic scale selects a 24-bit A/D conversion chip for data processing. The chip integrates regulated power supply, on-chip clock and signal amplification functions, without adding additional peripheral circuits, high integration, low cost and easy to implement, and it can be directly connected to MCU. All control signals are driven by the pins of the single-chip microcomputer, the circuit is simple, and there is no need to program the registers on the chip, thus reducing the difficulty of hardware and software design.

3. SCM control module

Considering the cost and power consumption of the electronic scale, the main control module of the intelligent electronic scale adopts 8051 series single-chip microcomputer, which is an 8-bit single-chip microcomputer with powerful functions and low price, which can fully meet the performance requirements.

4. Button module

Because the I/O port resources of the single-chip microcomputer are limited, the button module needs to be optimized and then connected to the single-chip microcomputer. This design uses matrix keys, which only need to be connected to the P3 port of the single-chip microcomputer, and the key positions are identified through line scanning. At the same time, software programming is used to eliminate the key jitter phenomenon and ensure the correct identification of key values. This keyboard design saves the I/O port resources of the single-chip microcomputer and improves the utilization rate of the I/O port of the single-chip microcomputer. This smart electronic scale is designed with a 4*4 film matrix keyboard, 0~9 on the keyboard is used to set the unit price, * is the decimal point, A is the accumulation function button, B is the reset function button, C is the peeling function button, Users can perform corresponding operations by pressing keys.

5. Display module

This intelligent electronic scale adopts LCD display. The hardware connection between LCD and single-chip microcomputer is simple. LCD has the advantages of low driving voltage, low power consumption, and long service life. It is a very commonly used display.

6. Overweight alarm circuit

The overweight alarm circuit is used to remind the user not to place too heavy objects for weighing, so as not to damage the sensor. It is composed of triode, luminous tube and buzzer.

4.The cause of electronic scale error

1. Four-corner eccentric load error

The weighing error of the electronic scale caused by the eccentric load of the four corners of the electronic scale is mainly due to the sensitivity of the sensor. The test for the eccentric load error of the four corners of the electronic scale is mainly after the electronic scale is loaded, and the position change of the measured item on the weighing platform will not cause Measure structural changes. The sensitivity of the load cell is different to a certain extent due to the gap between the production materials and the production process of the electronic scale resistance strain gauge and the load cell of the electronic scale, which causes the same excitation voltage, but due to the signal output of the load cell Different, so the four-corner eccentric load error is caused. In order to effectively reduce the error, a sensor with good impact resistance and anti-tilt ability should be selected, and a potentiometer should be connected to the branch of the signal output of the load cell. By adjusting the resistance value, the principle of resistive voltage division can be used. The signal output on the branch is balanced, so as to ensure the accuracy of the electronic scale measurement.

2. Weighing error

The main reasons for the weighing error of the electronic scale are as follows:

(1) Zero point drift The zero point drift is mainly due to the fact that the electronic scale is subjected to multiple impact loads of different sizes during the use of the electronic scale, resulting in many and complicated stress situations on the sensor, and when it reaches a certain limit, it causes the sensor of the electronic scale to fail. The contact point changes, which changes the original state of the sensor during verification, which leads to the appearance of weighing errors in electronic scales.

(2) Weighing platform Sassafras The rubbing of the weighing platform has a great influence on the transmission of force, which will cause the weight of the item to not fully act on the load cell of the electronic scale when loading heavy objects , As a result, the output signal of the load cell is relatively small. This situation mainly occurs when weighing a heavy object with a large load, and its display value will decrease, resulting in a weighing error. In view of the above-mentioned weighing errors, in the process of making electronic scales, we should first choose sensors with appropriate accuracy, quality and strong impact resistance, and then we should pay attention to the firmness and reliability of the sensors during the installation process, and we should have proper protection for the lead wires. , the scale body should have sufficient rigidity, and the protection device of the electronic scale should be reliable.

3. Discernment error

The ability of a scale to respond to small changes in an item's load during scale use is known as discrimination. The test of discrimination in the use of electronic scales is mainly to test the friction and connection of the scale body structure of electronic scales. Therefore, for electronic scales, the stress and friction in the connection are the causes of discrimination errors, and since discrimination errors are mainly aimed at small load changes, the resolution of weighing instruments and load cells of electronic scales The rate of impact on it is also very large.

4. Repeatability error

The repeatability error is mainly caused by the error of the output reading of the electronic scale after several tests under the same environment and the same load. In addition to the errors caused by wind force, gravity, humidity, and temperature during use, the repeat error of electronic scales also has repeat errors caused by the following points:

(1) Repeatability errors caused by electronic scale sensor conditions are not satisfied. In view of this situation, it is required that the electronic scale sensor’s excitation voltage, consistency of parameters and force transmission characteristics of the scale body during the use of the electronic scale, etc. All should meet the conditions, and the force transmission mechanism of the scale body of the electronic scale is required to avoid repeatability errors under the condition that the load on the sensor is proportional to the weight of the item.

(2) The repeatability error caused by the lateral force of the electronic scale sensor

Due to the influence of the environment during the use of the electronic scale, the load receiver may be displaced, resulting in the force of the sensor tilting or lateral force. The lateral force of the sensor is mainly in the design and manufacture of the force transmission mechanism. caused by errors in the process.

5.Electronic scale error solutions

1. Correctly used electronic scales

In the process of weighing items with an electronic scale, since the electronic scale is mainly weighed by a load cell, the items to be scaled should be handled with care during use. And the electronic scale should also be placed on a dry, ventilated, stable, and horizontal plane to ensure that the four feet of the electronic scale are stable, which can not only ensure the accuracy of weighing, but also play an important role in protecting the electronic scale.

2. Regularly verify the electronic scale

Due to the environment in which the electronic scale is used and the use time is too long, the components will age, and its accuracy will also be affected to a certain extent. Therefore, regular verification of the electronic scale can not only evaluate the measurement performance of the electronic scale, but also find out The reason for the accuracy of electronic scales, so regular verification of electronic scales has an important role and value in ensuring the accuracy of electronic scales and prolonging their service life.

3. Use high-performance single-chip microcomputer circuit

The single-chip microcomputer circuit is mainly used in the electronic scale, so in order to improve the accuracy and performance of the electronic scale, a high-performance single-chip microcomputer can be used, such as a FLASHROM with 8K bytes inside the single-chip microcomputer. The single-chip microcomputer with this performance is not only expensive Inexpensive, low power consumption, long life, and does not affect the output value anywhere.

The above are the details of the electronic scale solution introduced by Shenzhen Zuichuang Microelectronics Co., Ltd. for you. If you have electronic function development needs for kitchen scales, weight scales, body fat scales, and floor scales, you can trust us. We have rich experience in customized development of electronic products and can evaluate the development cycle and material prices as soon as possible. We are a number of chip agents at home and abroad, including MCU, voice IC, Bluetooth IC and modules, wifi modules. Our development capabilities cover PCB design, single-chip microcomputer development, software custom development, APP custom development, WeChat official account development and other hardware and software design. It can also undertake the research and development of smart electronic products, household appliances scheme design, beauty equipment development, Internet of Things application development, smart home scheme design, TWS scheme development, Bluetooth audio development, children's toy scheme development, and electronic education product development.

- TOP