Atomizer motor drive design

With the increasing global warming and air pollution, a series of lung diseases have also broken out. For lung diseases, atomization therapy is one of the most internationally recognized methods of treatment. The so-called atomization therapy is The nebulizer atomizes the drug and inhales it into the body, and directly enters the target organs such as the respiratory tract and lungs, which is faster and takes less medication than ordinary oral drugs. Therefore, this treatment method is widely adopted by major hospitals.

In order to have a better therapeutic effect, when using different liquid medicines for nebulization treatment for different users, it is best to use nebulizers with different atomization intensities according to the characteristics of the liquid medicine and the breathing speed of the patient. However, The atomizers in the prior art have the disadvantages that the atomization intensity cannot be adjusted, or only have limited operating gears, and the selectable range of the atomization intensity is small.

The compression atomizer based on the STM32 single-chip microcomputer has been greatly optimized in parameters such as atomization intensity and speed, and we can adjust it in a wide range in real time through button settings.

In addition, the use of the electronic control unit can also add some other auxiliary functions such as display and alarm to this compressed atomizer. It enables users to use the compression atomizer more quickly and effectively.

1. The overall block diagram design of the atomizer

In order to improve the reliability, stability and maintainability of the system, the design adopts the idea of modularization to design the hardware circuit. The single-chip microcomputer module is the core part of the design of the atomizer. It is mainly composed of the minimum system of the STM32 single-chip microcomputer and other hardware circuits to form the electronic control unit. The main functions of this module are: (1) Generate PWM modulation waveforms and send them as control signals to Motor drive module. (2) Process signals from the key module, etc., and send corresponding display information to the display module.

2. The motor drive module of the nebulizer

The main function of the motor drive module is to isolate the PWM modulation signal generated by the STM32 microcontroller and amplify its power. So that it can stably drive the compression motor, and can ensure the normal operation of the compression motor. The functions of the motor drive module are as follows:

(1) The output power reaches about 30W, which can drive high-power compression motors. (2) The driving circuit has high efficiency, can save power, and can also reduce the heat dissipation of the driving circuit. (3) The drive circuit has a good signal isolation effect on its input terminal. (4) No matter what kind of control signal or passive load is added to the motor drive circuit, it is safe.

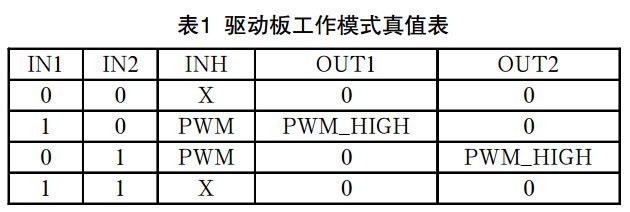

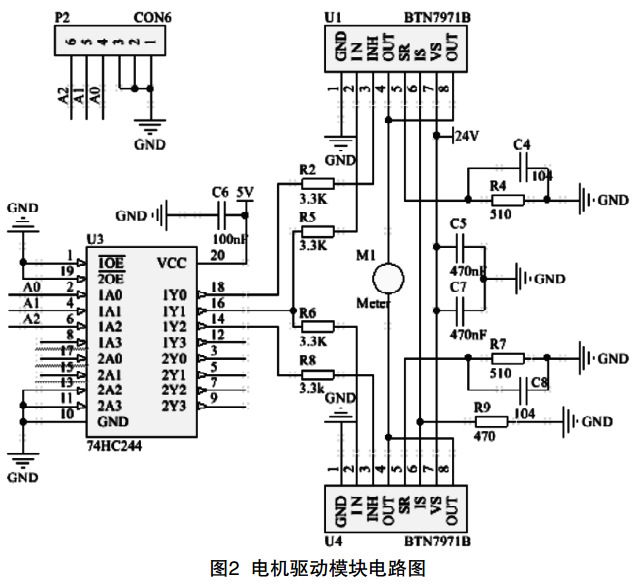

This module uses BTN7971B chips to build an H-bridge to drive the motor. The circuit is relatively complicated, but the H-bridge equipped with two BTN7971B chips has a strong drive capability, and the current output is about 68A. It also has stable speed regulation, small on-resistance, and low performance loss. Etc. 74HC244 eight-way positive-phase buffer/line driver is used to isolate and control the circuit to protect the main control chip. Its working truth table is shown in Table 1. Its circuit diagram is shown in Figure 2.

3. Software design of atomizer motor drive system

The PWM wave generated by the STM32 microcontroller is the core of controlling the operation of the compression motor; using the button module to realize the modulation of the PWM wave pulse width can change the speed of the compressor motor, thereby changing the degree of atomization; the button module also has functions such as selecting and setting user information .

epilogue

After testing, this motor drive circuit can output about 30W of power, which can fully achieve the purpose of stably driving a high-power motor; therefore, using the principle of this design can produce a compression atomizer that is more in line with market demand. In addition, the STM32 single-chip microcomputer can support a wide range of 32-bit applications and has powerful functions; making this compressed atomizer have good plasticity and developability in future production and life, we can customize the atomizer according to the different needs of users. In recent years, atomizers have become more and more popular. I hope this article can help the development of atomizers in the future.

The above is the design and development example of the atomizer motor drive introduced by Shenzhen Zuchuang Microelectronics Co., Ltd. for you. If you have a need for medical nebulizer solution development, you can rest assured to entrust it to us. We represent a variety of single-chip microcomputers, voice chips, dual-mode Bluetooth ICs, and wifi chips. Brands include Songhan MCU, Yingguang MCU, Jerry Bluetooth, Ankai Bluetooth, Allwinner, and Realtek. Our technical services include: PCB design, microcontroller development, Bluetooth solutions, software and hardware custom development, APP development, small program development, WeChat official account development, etc. It can also undertake the design of intelligent electronic products, the development of living appliances, the research and development of beauty equipment, the application of Internet of things platform, the smart home control system, the development of TWS earphones, Bluetooth earphone speakers, the development of children's educational toys, the design of electronic education products, etc.

Proposal recommendation

- TOP