- Home >> News >> Blog articles >> Appliances & Tools

Hardware development and design of the control board of the wall breaking machine

The main function of the broken wall cooking machine optimized in this paper is to make juice from fruit and vegetable materials. The principle is to crush the fruit and vegetable materials and water in a certain proportion to make juice. The motor of the cooking machine runs at high speed to drive the blade to collide with the broken material particles to achieve juice Effect. At present, the wall-breaking cooking machines on the market are mainly controlled by single-phase series motors. Due to the uncertainty of fluid motion, the load on the motor has random variations. The goal of optimization in this paper is to achieve precise control of the motor speed in the case of randomly changing loads, that is, under the condition of fluid reversal. And combined with the results of numerical simulation and experiment, it is concluded that the factor of speed has a great influence on the crushing effect, and the optimal design of its control system is conducive to improving the juice yield of materials.

Due to the mechanical characteristics of the series motor, when the load changes suddenly, the motor current will change greatly, the motor may be locked, and the electromagnetic interference caused by the motor to the external environment will be relatively large; at the same time, when the power is large, the temperature Rising fast, not suitable for long hours of work, these are the problems that need to be solved in the design.

1. The hardware principle of the broken wall cooking machine system

In the hardware circuit of the broken wall cooking machine, it is necessary to meet its technical and safety requirements. In terms of technology, limited by the size of the whole machine, the controller of the cooking machine is required to be small; in terms of safety, it is required that the product must not have a self-starting function if the power is turned off and on again during the operation of the product. Dangerous, it must be reset by a switch or button before it can be restarted to ensure the safety of the user.

According to the controllable phase-shifting full-wave control adopted by the speed regulation principle of single-phase series excitation motor, the hardware design of the power supply voltage zero-crossing detection circuit uses the moment of voltage zero-crossing as the time reference of the starting conduction angle; design the circuit of speed acquisition , The device is small in size, light in weight and easy to install, which is convenient for experimental operation; the motor drive circuit uses bidirectional thyristor as the control device, and safety protection circuits such as thyristor stall detection are designed to ensure safe and reliable operation of the motor.

The optimized design of the hardware system in this paper is designed around the drive control of the single-phase series motor. Its hardware scheme is shown in the figure above. The 220V AC input is surge protected. After the filter circuit, it is used as the input of the resistance-capacitance step-down circuit. After the resistance and step-down, the power is supplied to the 5V external DC power supply. The AMS1117 chip is used as the voltage regulator. , the AMS1117 chip samples the output voltage and feeds it back to the adjustment circuit inside the chip to adjust the impedance of the internal output stage adjustment tube, so that the output voltage is in a stable state of 3.3V, providing the working voltage for the microcontroller, and the other way as a single The input bus voltage of the phase series motor. The zero-crossing detection moment when the positive voltage of the power bus changes to negative is used as the time reference for adjusting the conduction angle of the thyristor, and the voltage signals of the two stages of the series motor are changed, so as to realize the speed control of the cooking machine. The speed of the motor is obtained by using the single-chip microcomputer to measure the output of the photoelectric sensor to generate the shaped pulse period, and then convert and calculate it. As the feedback amount of the system closed loop, the single-chip microcomputer gives the output of the controller according to the control algorithm, and drives the controllable motor through the thyristor control circuit. The silicon switch, according to the size of the conduction angle obtained by the control algorithm, realizes the precise control of the speed of the series motor.

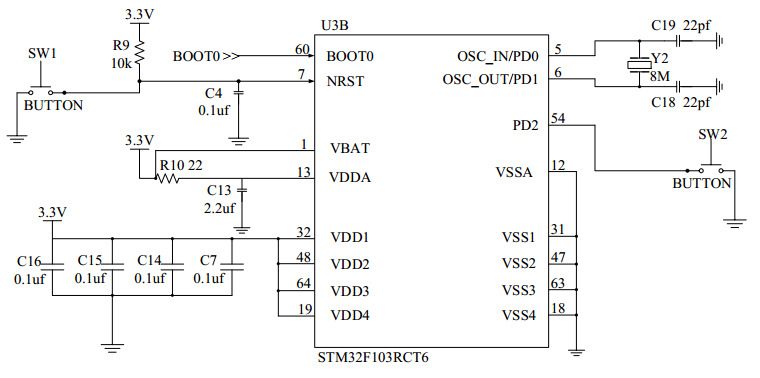

As the microprocessor, STM32F103RCT6 is used. The STM32F103RCT6 embedded chip is a 32-bit microcontroller with an ARM Cortex-M3 core launched by STMicroelectronics, and its operating frequency is 72MHz. The Thumb-2 instruction set supported by the ARM Cortex-M3 core makes STM32 have better instruction efficiency and stronger performance [72,73]. At the same time, the chip has rich communication interface resources and many high-performance peripheral resources.

The main control circuit of STM32F103RCT6 is shown in the figure below. The main control circuit mainly includes crystal oscillator, TTL level serial port, general I/O port and button start. The crystal oscillator circuit is mainly to provide the required working clock for the CPU and other circuits. Due to the limited precision of its internal high-speed clock, the external 8MHz crystal oscillator is used as the system clock to ensure the accuracy of the control system clock.

2. Circuit module design of the wall breaking machine

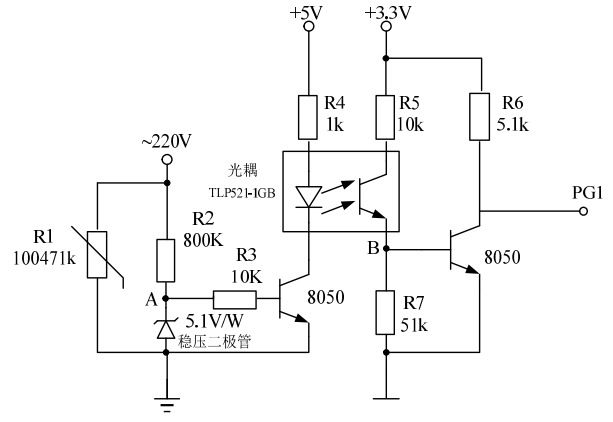

2.1 Zero-crossing detection circuit

The cooking machine needs to control the conduction angle of the thyristor to realize the motor speed control, and the quality of the zero-crossing signal detection circuit plays a vital role in the speed regulation performance of the cooking machine. The zero-crossing detection circuit is shown in the figure below. When the AC point is positive half-wave input and the voltage is greater than 5V, the Zener diode reversely breaks down, so that the voltage at point A is maintained at 5V, and the light-emitting diode in the optocoupler is driven by the amplified current of the triode 8050. At this time, the emitter of the triode is forward-biased , the collector is reverse-biased, so PG1 is low. On the contrary, when the AC negative half-wave is input, the Zener diode is forward-conducting, PA=0, and the triode 8050 is in the cut-off state. When the optocoupler is also in the off state, then PB=0, and the triode is in the off state, so PG1 is at high level at this time.

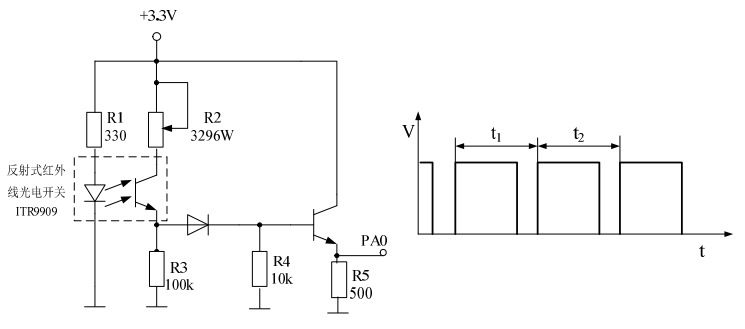

2.2 Speed detection circuit

The cooking machine system in this paper is a speed closed-loop control system. The main purpose of its control is to achieve constant value control of different speed settings, so accurate speed feedback is very important for system performance. This article mainly uses the reflective infrared photoelectric switch ITR9909 to cooperate with the corresponding circuit to detect the speed, as shown in the figure below. The main principle is that when the reflective infrared switch detects the reflected light, the NPN triode is in the amplified state, and PA0 is set to high level; on the contrary, when the photoelectric switch does not detect the reflected light, the triode is in the cut-off state, and PA0 is set to at low level.

As a result, when the motor is running, the infrared switch is blocked intermittently, and the circuit inputs a square wave signal to the microcontroller microcontroller, and uses the input capture program. At the rising edge of the square wave, a capture interrupt service flag is generated. At this time, the timer starts counting and ends until the rising edge of the next square wave ends. The time information represents the time taken by the motor to rotate one cycle. The cycle time is obtained through input capture and converted into the speed data of the motor. The sensitivity of the photoelectric switch can be changed by adjusting the resistance of the potentiometer.

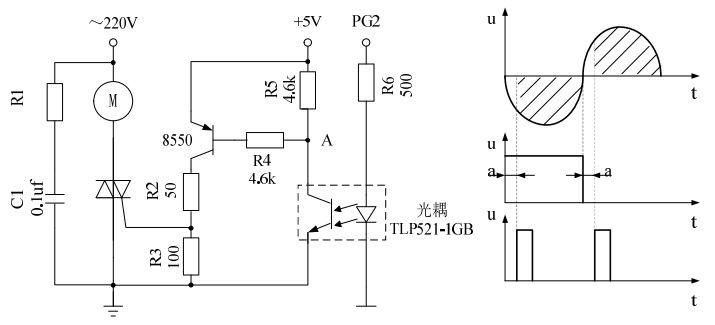

2.3 Motor drive circuit

The series-excited motor used in the cooking machine realizes the speed control of the motor through the speed regulation of the thyristor. The motor drive circuit is a key part of the cooking machine. Reliable drive circuit and control signal are the guarantee of actual motor speed regulation. The principle and basic structure of the series-wound motor is a DC series-wound motor. The stator winding is a 2-pole concentrated winding, and the rotor has a wire-wound distributed winding, and has a commutator and carbon brushes to change the direction of the current flowing into the rotor. . The series-wound motor has the advantages of large starting torque, high efficiency, and convenient speed regulation. Due to the simple control circuit, the cost of the series excitation motor is lower than that of other variable speed motors. The maximum speed of the series excitation motor for cooking machines can reach more than 12,000 revolutions per minute when the cooking machine is running, and the load is driven by the reduction box. The figure below is the motor drive circuit of the cooking machine.

The main principle of its motor drive circuit is that when PG2 is at a high level, the light-emitting diode in the optocoupler works normally, the voltage at point A is zero, the emitter of the PNP transistor 8550 is forward-biased, the collector is reverse-biased, and the triode is in the amplified working state, then PB >0, the bidirectional thyristor (silicon controlled rectifier) is turned on, and the motor runs normally. On the contrary, when PG2 is at low level, the triode is in cut-off state, PB is zero, and the conduction angle of the thyristor cannot be triggered, and the motor stops working.

The above is an example of the optimized design of the breaker control board introduced by Shenzhen Zuchuang Microelectronics Co., Ltd. for you. If you have a need for the development of a wall breaking machine solution, you can rest assured to entrust it to us. We represent a variety of single-chip microcomputers, voice chips, dual-mode Bluetooth ICs, and wifi chips. Brands include Songhan MCU, Yingguang MCU, Jerry Bluetooth, Ankai Bluetooth, Allwinner, and Realtek. Our technical services include: PCB design, MCU development, Bluetooth solution, software and hardware custom development, APP development, small program development, WeChat official account development, etc. It can also undertake the design of intelligent electronic products, the development of living appliances, the research and development of beauty equipment, the application of Internet of things platform, the smart home control system, the development of TWS earphones, Bluetooth earphone speakers, the development of children's educational toys, the design of electronic education products, etc.

Proposal recommendation

- TOP