- Home >> Solution >> Appliances >> cookers

Bottle warmer solution

As people's pace of life accelerates, the feeding standards and needs for infants and young children are also getting higher and higher. What is widely promoted on the current market is an automatic milk warmer that integrates heat preservation and heating. One is to use a mechanical thermostat directly in series in the heating circuit, and use a bimetal as a temperature sensing element to control the heating temperature; the other is to use the delay of the oscillating circuit to maintain the set temperature in the control circuit, and use a resistor The thermistor whose rate changes with temperature changes is used as a temperature sensing element to control the temperature of the circuit to ensure the constant original temperature.

Such a milk warmer is convenient, quick and easy to operate, and ensures that the fluid that can be heated through water is kept at a certain suitable temperature, which greatly facilitates the feeding work of infants and young children. However, traditional infant feeding methods have been criticized by current scientific research. The correct way to prepare formula milk powder is: first add boiling water to the feeding bottle, then put in an appropriate amount of milk powder, then rinse the feeding bottle under cold water to quickly cool down the milk powder, and then feed infants when the appropriate temperature is reached. In this way, nutrients such as milk protein, nucleotides, and fat in dairy products will not be destroyed. And because it is difficult to control the temperature of this brewing method, many parents even let the milk cool down because they are busy with other things and need to reheat it. Dairy products cannot be reheated. Heat treatment will reduce the stability of milk. The most important reason for this reduction in stability is the complex interaction between milk proteins. Denatured milk protein is very harmful to the body of infants and young children, so a device with sound and light reminders for heat preservation, rapid cooling to an appropriate temperature, and the ability to set the temperature and switch heating modes is needed.

1. Structural design of temperature-regulated milk warmer

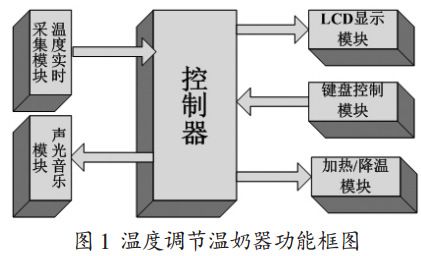

The article improves on the heating principle of the traditional milk warmer, adopts single-chip microcomputer as the controller, and adds temperature display module, temperature adjustment module, sound and light music module, heating/rapid cooling module. Here, the low-temperature ceramic plate heating plate is used for heating and heat preservation to increase the heating area to make the heating uniform. A DC fan is installed on the heat preservation base to achieve the purpose of rapid cooling by accelerating the air flow. The specific functional block diagram is shown in Figure 1.

Here choose AT89C5131 of ATMEL Company as the controller. AT89C5131 is a microcontroller based on 52 cores. DS18B20 is selected externally as the digital temperature sensor of the temperature sensing element. The chip adopts a single bus interface to connect with the microprocessor to realize two-way communication. An LCD is added to display the set temperature and function mode, among which the I/O port P1. 5 Connect the temperature sensor; P2.2 connect the music module and play nursery rhymes when the temperature reaches the set value; P3.5~3.7 connect the LED indicator light for temperature alarm, normal operation after booting, etc.; P2.5 connect the heating chip, P2.6 Connect to the fast cooling fan; P0.0~0.7 connect to the LCD display. AT89C5131 has a keyboard interface that allows connection with 8*N matrix keyboards, its input has high or low level programmable interrupt capability, and P1.1~1.3 and P3.3, P3.4 are connected to keys. In addition, AT89C5131 is also connected with some peripherals such as power supply and drive circuit.

2. Software design of temperature adjustment milk warmer

2.1 Design idea of milk warmer

On the basis of hardware circuit design, the software adopts the form of functional modules according to its characteristics, and mainly uses the general program structure combining interrupt and subroutine call to write the lower computer software. The article is developed in C language, and the development environment is KEILμVision4 of LEIL Software Company. The software generally presents the characteristics of good organization, clear structure and scalability.

2.2 Function introduction of milk warmer

The specific functions to be realized by the temperature-adjustable milk warmer to be realized in the article are as follows.

(1) The temperature range of heat preservation can be set by pressing the button, instead of a specific temperature, so that the fuzzy control algorithm can avoid the misoperation and false alarm of the controller;

(2) Set three operating modes: rapid cooling mode, primary heat preservation mode, and basic heat preservation mode. Different time and different low-temperature heating modes can be used for different foods. When the rapid cooling mode is activated, the cooling fan on the base runs, causing the food to quickly drop to the set temperature range, and the fan stops. The one-time heat preservation mode runs automatically, and the heater runs to keep the temperature constant. Can be operated manually or automatically;

(3) Due to the particularity of food for infants and young children, try to ensure the least loss of nutrition. Avoid repeated heating of dairy products, so the program sets dairy products to be heated only once, and the heating time is controlled at 5 minutes;

(4) Use the LCD to display the set temperature range and the selected mode code, which can make the user's operation more convenient;

(5) When the heat preservation and heating time are up, the reminder mode with indicator lights and children's songs is more childlike.

2.3 Program flow of the bottle warmer

The programming idea of the main body of the article is to use the module subroutine to call and interrupt the system. The system is powered on and enters the initialization state. First, the display subroutine is called to start the self-test, which is intended to display the temperature of the thermal insulation base, the heating mode and the set temperature range. If the food that needs to be heated or kept warm has been placed on the heat preservation base at this time, the program scans whether the set time is reached. After the time is up, the keyboard processing and temperature control program will start.

(1) Mode selection: Press the keyboard to set the operating mode. If it is the rapid cooling mode, the system will collect the temperature in real time. If it is not within the temperature range set by the system, the cooling fan will be activated. The speed of the fan is controlled by frequency, and a certain frequency is programmed by interrupt timing to output from the IO port to achieve four stages of wind speed. The wind speed is automatically adjusted according to the difference close to the set temperature, so as to enter the suitable temperature range more quickly and accurately.

(2) Temperature setting: If the keyboard starts to set the temperature range, the keyboard is pressed, the system enters the real-time temperature acquisition stage, the CPU calculates, processes and displays, and at the same time sends the real-time temperature data to the temperature range set by the keyboard before. In comparison, if it is within this range, it means that the temperature has reached an appropriate range, and the music sound and light program is started to remind the user that the heat preservation is completed. According to the functional requirements, according to the heating mode set by the keyboard, the program jumps to the corresponding subroutine: one-time heating mode and repeated heating and heat preservation mode.

3. Feasibility analysis of milk warmer production

The temperature-adjustable milk warmer introduced in the article is still in the design and test stage, and whether it can enter the product production stage still needs a series of market research and product evaluation. The feasibility analysis of the current experimental stage is as follows.

(1) Functional analysis: the basic functions can be realized in the test stage, the temperature error is controlled within 2°C, the heating and rapid cooling time is between 3 minutes and 5 minutes, and the software can be used in the design stage according to the different foods to be kept warm. Setting; (2) Economic analysis: The hardware structure of this design is simple, low cost, and the main control circuit is small in size, which is suitable for mass production; (3) Safety analysis: The circuit is powered by +5V, and the 220V AC power supply is used The AC adapter is converted to DC low-voltage power supply, and the fuselage has no risk of electric shock; the heating module is heated at low temperature, without the risk of scalding, and has excellent safety performance.

Summarize

This temperature-regulated milk warmer is different from traditional heating, and it is more stable, efficient and easy to operate with a single-chip microcomputer control. After repeated debugging and experiments, the performance of the system fully meets the requirements of various design indicators. Due to the adoption of modular structure design and programming, it has good flexibility and expansibility.

With the general improvement of infant feeding requirements, there is an urgent need for small household appliances that are simple, efficient, and integrated with multiple functions. The single-chip microcomputer selected in this article has strong software and hardware development capabilities. Based on the optional heating mode, more practical functions are expanded.

The above are the details of the bottle warmer solution introduced by Shenzhen Zuichuang Microelectronics Co., Ltd. for you. If you have the development and design needs of a milk warmer, you can trust us. We have rich experience in customizing and developing electronic products. We can evaluate the development cycle and IC price as soon as possible, and can also calculate the PCBA quotation. We are a number of chip agents at home and abroad: Songhan, Yingguang, Jieli, Ankai, Quanzhi, realtek, with MCU, voice IC, Bluetooth IC and module, wifi module. Our development capabilities cover PCB design, single-chip microcomputer development, Bluetooth technology development, software customization development, APP customization development, WeChat official account development and other hardware and software design. It can also undertake the research and development of smart electronic products, the design of household appliances, the development of beauty equipment, the development of Internet of Things applications, the design of smart home solutions, the development of TWS earphones, the development of Bluetooth earphone speakers, the development of children's toys, and the development of electronic education products.

- TOP