- Home >> Solution >> Appliances >> cookers

Home Meat Grinder Solution

In recent years, the meat industry has achieved rapid development, and the variety of meat deep-processing products such as ham sausage and enema is increasing day by day. The accuracy of emulsified particle size of fish, chicken, pork and other meat directly affects the quality of ham sausage, enema and other products. The meat grinder can only achieve a single meat grinding function or even emulsification, the emulsification particle size is single and the accuracy of the meat emulsification particle size is low. Low power consumption, increasingly enhanced control functions, and the rapid development of the ever-increasing variety of single-chip control technology and smart instrument technology provide favorable conditions for the transformation of the control system. For this reason, this test uses single-chip control technology and adds temperature at the input end of the single-chip microcomputer. The analog signal of detection and emulsification particle size detection is compared with the given required signal by comparing these analog real-time detection signals to realize the automation and intelligent control of the temperature, speed and particle size of the meat grinder, ensuring the accuracy, safety and stability of the equipment Run to meet the requirements of various sizes and different granularities. The system not only has the highly automatic control function of the production process, according to the requirements of the processed products, it can automatically control the action of the execution object, but also has the function of real-time monitoring and modern management. Perform data statistics and production data tables and other management functions on the production situation according to the user's requirements. After nearly two years of operation practice, it shows that the system has reliable performance, high degree of automation, convenient operation, and remarkable economic and social benefits.

1. The composition and working principle of the meat grinder equipment

1.1 Equipment Composition

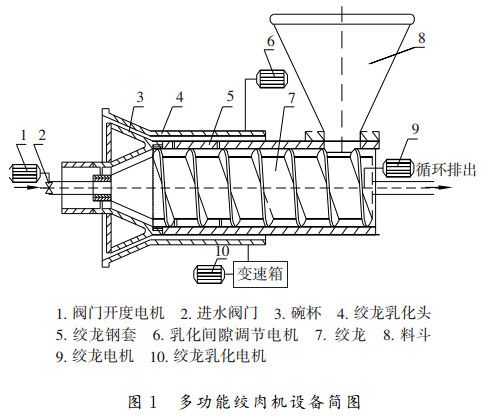

The multifunctional meat grinder designed in this experiment realizes the organic combination of three functions of bone removal, meat grinding and emulsification, and adopts fuzzy PID control technology and stepping motor subdivision control technology to meet the requirements of various sizes and different particle sizes with high precision. A schematic diagram of the multifunctional meat grinder equipment is shown in Figure 1.

The multifunctional meat grinder is composed of a hopper, an auger, an auger cylinder liner, a bowl cup and a meat emulsifying head. The sieve holes in the front section of the auger liner are selected according to the processing of different types of bone-in meat. Cutting is carried out, the inner surface of the emulsifying head cone and the outer surface of the bowl cup are divided into three sections, and there are rectangular grooves with an inclination angle of 200° to the axis respectively, but the direction of the middle groove is opposite to that of the first and last grooves, and the size of the groove at the right end is the same as that of the helical groove. The size of the knives is matched, the size of the three grooves decreases from right to left, and the tendency of the emulsifying head and the bowl groove is opposite. The gap between the ground meat emulsifying head and the bowl is adjusted by driving the nut fixed on the thrust bearing seat of the ground meat emulsifying head to move horizontally and linearly through the driving screw, and the size of the gap controls the size of the emulsified particle size. The power equipment auger motor, meat emulsification motor, emulsification gap adjustment motor and valve opening adjustment motor complete the meat grinding, emulsification, gap adjustment, and valve opening control respectively.

1.2 The operation process of the meat grinder

First, according to the type of processed meat, manually select the auger sleeve with a suitable sieve hole diameter, install and fix it and start the system, the small piece of meat with bone is conveyed and squeezed by the auger, and the meat is squeezed out from the sieve hole of the auger cylinder liner. The meat-ground emulsification motor drives the spiral knife on the inner wall of the meat-ground emulsification head to rotate and cut off the shredded meat. After being sent to the gap between the conical emulsification head and the bowl, it is emulsified by high shear. Adjust the size of the emulsification gap to control the emulsification particle size. The emulsification gap is adjusted to It can achieve a single meat mincing function at the maximum. During the emulsification process of the ground meat, to prevent the meat from deteriorating at high temperature, the cooling water is passed into the hollow of the auger and the bowl, and the temperature sensor at the outlet pipe of the circulating water detects the temperature in real time. When the temperature is high, the opening of the water inlet valve is increased. ; When the temperature is low, reduce the opening of the water inlet valve.

2. The hardware composition of the meat grinder control system

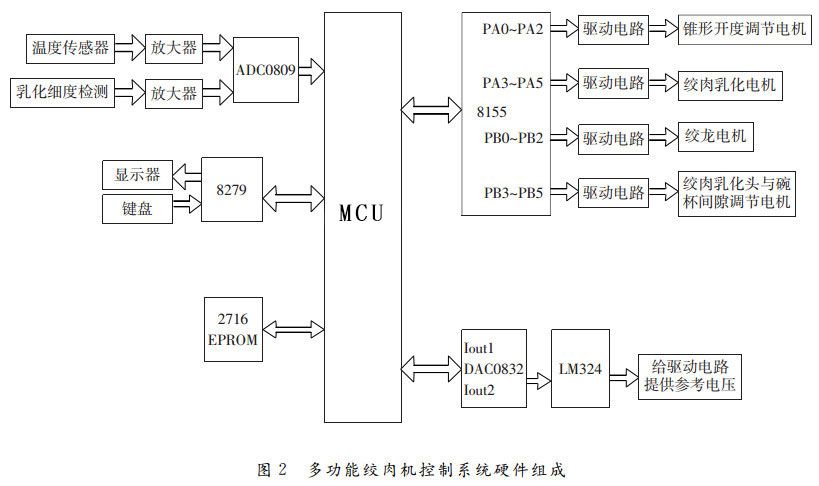

System hardware composition, as shown in Figure 2. The system is based on low-voltage, high-performance, low-power, and cheap 8-bit CMOS single-chip microcomputer. In order to expand the I/O port, a programmable keyboard display interface chip 8279, an A/D conversion chip ADC0809, and a programmable Erase programmed EPROM2716, multi-chip D/A conversion chip DAC0832 and a programmable parallel interface chip 8155. According to the address to be accessed, if the chip select signal of the chip is low level, the corresponding chip is selected.

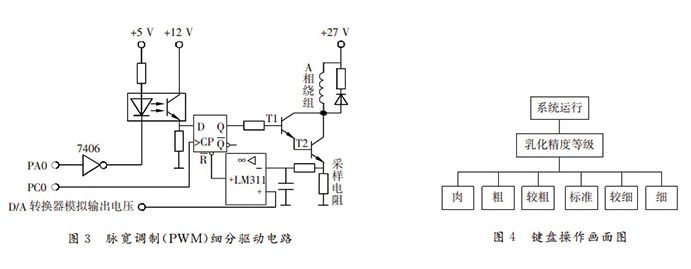

In order to improve product quality and ensure emulsification accuracy, stepping motors are used in all four power equipment. When the stepper motor receives one pulse, it will rotate the angle corresponding to one pulse, with high positioning accuracy and no cumulative position error. The biggest feature of the stepper motor that is different from other motors is controlled by pulse signals. It is a digital motor, that is, when there is a pulse, just set the corresponding output terminal to 1; when there is no pulse, just set the corresponding output terminal to 0, which shows that the pulse distribution It's easy to do with software. Because the driving current of the stepping motor is large, the I/O driving capability of the single-chip microcomputer is limited, so a driving circuit should be added between the stepping motor and the single-chip microcomputer. In order to prevent the stepper motor from oscillating during operation, a subdivision circuit power supply is used here to reduce the pulse width modulation (PWM) type subdivision drive circuit of the stepping motor step angle, as shown in Figure 3. The driving circuit is composed of three parts: photoelectric coupling circuit, power amplifier circuit and pulse width modulation circuit. The pulse width modulation circuit is to convert the analog current signal output by the D/A conversion chip DAC0832 of the single chip microcomputer into a voltage signal through the operational amplifier, and this voltage is used as the reference voltage of the non-inverting input terminal of the voltage comparator in the pulse width modulation circuit. The voltage signal measured on the sampling resistor in the power amplifier circuit is compared with the reference voltage of the non-inverting input terminal. When the detected voltage is greater than the reference voltage, the output of the voltage comparator is low, making the output of the D flip-flop low, which will make The power amplifier tube is cut off, otherwise, the power amplifier tube is turned on. The purpose of the pulse width modulation circuit is to obtain a voltage consistent with the analog output voltage of the D/A converter on the sampling resistor, so as to ensure that the average current on the motor winding meets the requirements. By controlling the on-off time of the power amplifier tube, that is, when the average current requirement on the motor winding is large, the conduction time of the power amplifier tube must be increased; when the average current requirement on the motor winding is small, the conduction time of the power amplifier tube must be shortened. Since the motor winding is an inductive load, the characteristic current of the inductive load cannot be mutated, which hinders the change of the current, and the modulation frequency of the pulse width modulation circuit is relatively high, generally greater than 20kHz. Working mode, but the current in the motor winding is still relatively stable. The pulse width modulation subdivision drive circuit has high control precision and stable operating frequency, and is mostly used in occasions with high requirements for comprehensive drive performance.

3. Functional control of the multi-functional meat grinder program

The goal of the intelligent control of the multifunctional meat grinder: on the premise of ensuring the safe and stable operation of the production process, produce a variety of qualified and high-precision emulsified products according to the requirements of emulsified fineness, and at the same time ensure that the system has a relatively fast speed and equipment efficiency High, reduce labor intensity and production cost. The main control contents of the control system are as follows.

3.1 Program preselection function

The keyboard operation screen is shown in Figure 4. On the screen, each rectangular box is equivalent to a button. For example, after pressing the system to run, the single-chip microcomputer scans each button circularly. When a button is detected to be pressed, the key value is stored in the 8279 chip FIFORAM, and the scene is protected. Read the key value and execute the keyboard processing program that has been compiled. That is, after touching the box of "meat", the keyboard processing program of the key of "meat" is executed, that is, the meat processing program. System programs include public programs and processing programs for various emulsification fineness requirements such as meat, coarse and coarse. Execute the corresponding program through the jump command, if you choose meat, it will skip other emulsification fineness grade processing programs and only execute the meat processing program. So on and so forth.

3.2 Stepping motor subdivision control technology

The subdivision control technology is realized through the software programming of the subdivision circuit power supply and the hardware equipment of the pulse width modulation (PWM) type subdivision drive circuit. The working principle of the pulse width modulation (PWM) subdivision drive circuit has been introduced. The key to the subdivision control technology is how to provide reference voltages of different sizes to the subdivision drive circuit, that is, how to transmit appropriate data to the D/A conversion chip. DAC0832 data input.

3.3 Temperature control technology

Prevent high-temperature meat from deteriorating and detect temperature in real time. In order to maintain a constant temperature, intelligent PID fuzzy control is adopted, and the temperature deviation value (difference between temperature detection value and given value) e and temperature deviation change rate △ e are input variables of intelligent PID fuzzy control. According to the size of e and △e, their values are fuzzified, and they are divided into seven fuzzy states: negative large, negative medium, negative small, zero, positive small, positive medium, and positive large. The PID parameters such as coefficient kI and differential coefficient kD are adjusted online, and the variation of the opening degree of the cone valve is calculated according to the adjusted parameters, so as to determine the speed and number of rotation steps of the stepping motor that adjusts the valve opening degree. In the software programming, the speed and number of steps of the stepping motor corresponding to the variation of opening degrees of different sizes have been stored. The speed of the motor is found through the table lookup program, and the time of each beat is calculated according to it, thereby changing the timing. The initial value of the device changes the interval time of sending different data to the D/A conversion chip.

3.4 Emulsification fineness control

For emulsified products with a certain fineness requirement, in order to ensure accuracy and improve efficiency, the gap between the conical emulsifier head and the bowl cup is adjusted to the maximum at the beginning of processing (different fineness, the maximum value is different), the auger motor and the meat emulsification motor The speed is adjusted from slow to fast along a certain curve, and when it reaches a certain time (a certain number of steps), the gap between the conical emulsifying head and the bowl cup is automatically adjusted to an intermediate value, and the speed of the auger motor and the meat emulsifying motor is adjusted to be faster The range increases, and the speed along a certain curve changes from slow to fast. When a certain time (rotating a certain number of steps) is reached, the gap between the cone emulsifying head and the bowl cup is automatically adjusted to the minimum, and the auger motor and the meat emulsifying motor The speed follows the adjustment until the fineness requirement is met. The speed of each motor mainly depends on the time of each shot, and the time of each shot is changed by software programming of the timer. As long as the initial value of the timer is changed, the time of each shot can be conveniently controlled.

In addition, in view of the fact that the gap between the conical emulsifying head and the bowl is an important parameter affecting the emulsification accuracy, based on years of experience, the author compiled a corresponding table and look-up table for the maximum, middle, and minimum gap values corresponding to various emulsification products Program, when it is found that the emulsification accuracy does not meet the requirements, change the value of this table at any time.

conclusion

The control system takes the single-chip microcomputer control technology as the core, realizes the organic combination of the three functions of bone removal, meat grinding and emulsification, and is designed by comprehensive application of modern and advanced automation technology. Cooperate with the software to provide subdivision power supply, so that the stepping motor step angle is reduced, the operation is stable, the vibration is small, and the precision is high. The software design can easily change the initial value of the timer according to the needs, and can conveniently control the time of each beat and change the speed of each stepping motor. The system better controls the interlocking requirements between the speeds of each motor, realizes the intelligent control of temperature and speed, and realizes the high-precision control of various emulsification finenesses. In addition, when the variety of emulsification needs to increase, the software can be easily changed to achieve it, and the system has strong flexibility and expandability.

The above are the details of the meat grinder solution introduced by Shenzhen Zuchuang Microelectronics Co., Ltd. for you. If you have the electronic function development needs of the meat grinder, you can rest assured to entrust it to us. We have rich experience in custom development of electronic products, and can evaluate the development cycle and IC price as soon as possible, and can also calculate the PCBA quotation. We are a number of chip agents at home and abroad: Songhan, Yingguang, Jieli, Ankai, Quanzhi, realtek, with MCU, voice IC, Bluetooth IC and module, wifi module. Our development capabilities cover PCB design, single-chip microcomputer development, Bluetooth technology development, software customization development, APP customization development, WeChat official account development and other hardware and software design. It can also undertake the research and development of smart electronic products, the design of household appliances, the development of beauty equipment, the development of Internet of Things applications, the design of smart home solutions, the development of TWS earphones, the development of Bluetooth earphone speakers, the development of children's toys, and the development of electronic education products.

- TOP