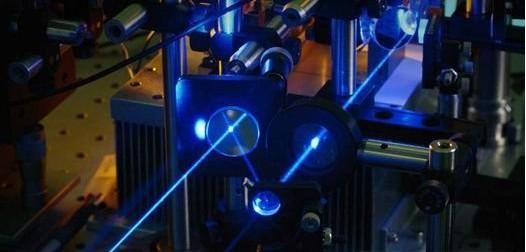

It’s about to get hot! High power ultrafast fiber laser

Ultrafast lasers with pulse durations in the femtosecond and picosecond range currently play an important role in many industrial manufacturing processes, the value of these lasers in high-quality, "cold processing", coupled with laser technology, process development, beam Advances in handling and delivery have opened the door to numerous advanced scientific and industrial applications.

Now, state-of-the-art technology using tapered double-clad fiber (T-DCF) amplifiers offers the prospect of a high-power development in a space-efficient format with excellent beam characteristics and, most notably, at a production cost only less than that of ordinary Fiber high. This means that the cost per watt of these ultrafast lasers is increasingly important, enabling a rapid return on investment through increased processing speed and precision.

The output power of rare-earth-doped fiber sources has risen dramatically over the past decade through the use of cladding-pumped fiber architectures such as the NKT Photonics aeroGAIN-ROD1, resulting in a range of fiber-optic devices with superior beam quality, overall efficiency, and operating Performance in terms of flexibility in wavelength and radiation format. Although new configurations such as the Amphos InnoSlab technology have also enabled significant advances in solid-state high-power ultrafast technology, the high cost of solid-state gain materials and thermal management challenges may still pose a significant barrier to their widespread adoption.

The European Commission (EC) has funded the PULSE project to support the development of competitive technologies that enable faster, more precise and athermal laser manufacturing. Amplionyx Oy and a consortium of European partners including Fiat Chrysler are now developing a T-DCF laser that can deliver up to 2.5 kW of power with pulse durations as short as 100 fs and repetition rates up to 1 GHz. The complete laser processing system will use polygon scanner technology and fiber-integrated optics to process high-power ultrashort pulses at scanning speeds up to 1.5 km/s, thereby providing spots as small as 10 μm.

The rise of high-power ultrafast fiber lasers

Ultrafast pulsed lasers have grown exponentially, with the number of patent applications filed increasing fivefold from about 100 to 500 per year. Femtosecond laser processing benefits many advanced niche applications, including in photonics, microelectronics, MEMS and many other markets.

Fiber lasers, solid-state lasers, and disk lasers are the most promising candidates for generating high average power. Compared with solid-state and disk lasers, fiber lasers stand out for their compact size, robustness, high efficiency, easy thermal management, and reliable beam quality. Significantly reduced production and maintenance costs also make fiber-based approaches very attractive for the development of picosecond and femtosecond high repetition rate kilowatt-class lasers.

Today's high average power fiber lasers typically employ chirped pulse amplification (CPA), however, in boosted fiber-based amplifiers, even for highly extended pulses, the optical peak intensity can become very high, producing detrimental non- Linear pulse distortion can even damage the gain medium or other optical components. Furthermore, in pulsed high-power systems, other nonlinear effects such as self-phase modulation, stimulated Raman scattering (SRS), mode instability, and poor output beam quality often arise, limiting their performance.

The main way to solve the problem of pulse signal amplification is to increase the core diameter of the optical fiber. Special active fibers with large modal areas were developed to increase the ratio of active fiber surface area to active volume, thereby improving heat dissipation and increasing the threshold of nonlinear effects for power scaling. State-of-the-art high-power fiber-based technologies have achieved >1 kW in a single pulse amplification channel2 and lay the foundation for future ultrashort multi-kilowatt fiber laser systems.

Several active fibers with large effective mode area (LMA) have been developed to achieve high power scaling. They are well-known LMA fibers with low-pore cores, microstructured rod fibers, spiral cores or chiral coupled core fibers and T-DCF. The mode field diameter (MFD) obtained with these low-aperture technologies typically does not exceed 20–30 μm. Microstructured rod fibers have larger MFD up to 65 μm and perform well. Recently, a femtosecond master oscillator power amplifier (MOPA) containing large pitch fiber (LPF) demonstrated an impressive pulse energy of 2.2 mJ. However, the fabrication of LPFs is very complex and requires extensive technical processing, such as precision drilling of fiber preforms, resulting in higher production costs. These fibers are also very sensitive to bending, which means that it may be difficult to achieve sufficient robustness, and it is difficult to envisage reasonable production costs using LPF.

Overcoming nonlinear effects in fiber laser power scaling

T-DCF is one of the promising alternatives to high-power fiber-based CPA systems, which can minimize nonlinear effects while simplifying the normal multi-stage amplification chain by replacing it with a single stage. T-DCF is a double-clad fiber formed using a special fiber drawing process in which the temperature and pulling force are controlled to create a taper along the length of the fiber, by using a pre-clad fiber preform, core and inner cladding and inner cladding Both the diameter and thickness of the layers vary along the entire length of the fiber.

The result of forming a tapered geometry of a double-clad fiber is that light introduced into the thin end propagates in the wide core without changing the mode content. It is well known that sequentially increasing the diameter of multiple series of cylindrical fiber amplifiers generally increases the threshold of unwanted nonlinear effects, the T-DCF design incorporates this advantage in a single fiber, and as a result, the optical amplification increases by increasing the nonlinear effects (including Brillouin and Raman scattering) to maintain excellent beam quality.

Due to its specific geometry, the T-DCF technique can be used to directly amplify a wide range of pulse signals: from short (tens of picoseconds) to long (up to hundreds of nanoseconds) and narrow (tens of picoseconds) picometers ( meters) to wide linewidths (tens of nanometers). According to the study, using a tapered fiber with a maximum end core diameter of 200 μm with a numerical aperture (NA) of 0.11, peak power and energy amplification levels were recorded, and a 60 ps pulse with 300 μJ energy without nonlinear distortion was recorded.

The fiber's double-clad structure means that its core can be pumped at higher powers than can be propagated in the core alone, compared to cylindrical fibers with similar levels of active ion doping, in tapered fibers The absorption and conversion of the pump light per unit length in is higher due to the improved cladding mode mixing and the higher absorption at the thicker end of the cone due to the thicker cladding, which also means that the rare earth ions Dopants can be efficiently concentrated at the broad end of the T-DCF because the geometry makes their presence proportional to the square of the diameter.

T-DCF is simple to produce and compact to assemble

One of the biggest advantages of T-DCF is its simplicity of production. The preform production of special high-power fibers (microstructured rod fibers, 3C or LCF) involves complex technology and strict structural requirements, in contrast, T-DCF is made using standard fiber preforms. With a simple production technique that varies the drawing speed during the drawing process, which causes the fiber diameter to vary along its length, the production of T-DCF is almost as simple as that of conventional reactive fibers. The diameter of T-DCF fiber can be reduced to 35 cm, which allows high-power amplifiers to be packaged very compactly without loss of performance.

Proposal recommendation

- TOP