- Home >> Solution >> Appliances >> cookers

Induction cooker solution

Induction cooker, also called induction cooker, uses the principle of electromagnetic induction for heating. It is an advanced electronic cooker for cooking food in modern families. It is very convenient to use and can be used for various cooking operations such as boiling, frying, frying, steaming and frying. Features: fast heating, high thermal efficiency, no open flame, no smoke, no harmful gas, no heat radiation to the surrounding environment, small size, good safety and beautiful appearance, etc., can complete most of the cooking tasks of the family, is the realization of The new electronic cooker is indispensable for the modernization of the kitchen.

1. Commonly used heating methods for electrical appliances

Most household appliances need to be heated. There are usually two methods for heating with high-frequency voltage or current: dielectric heating and induction heating.

1. Dielectric heating

This is heating using high-frequency voltage, usually used to heat non-conductive materials. When a high-frequency voltage is applied to the two poles, an alternating electric field will be generated between the two poles. The medium to be heated is in an alternating electric field, and the polar molecules or ions in the medium will rotate or vibrate at the same frequency with the electric field, thereby generating heat and achieving the heating effect. Such as microwave heating.

2. Electromagnetic induction heating

This is to use high-frequency current heating to generate an alternating magnetic field through the components of the electronic circuit board. When the furnace surface is placed on the bottom of the iron-containing pot, the pot will cut the alternating magnetic field line and generate an alternating magnetic field on the metal part of the bottom of the pot. The current and eddy current make the iron molecules of the pot move at high speed and irregularly, and the molecules collide with each other and rub against each other to generate heat energy (so: the heat source of the induction cooker comes from the bottom of the pot instead of the induction cooker itself. The heat is transmitted to the pot, so the thermal efficiency is better than that of all cookers. The efficiency is nearly 1 times higher) so that the appliance itself generates heat at high speed, which is used to heat and cook food, so as to achieve the purpose of cooking. This is the principle of induction heating, and the induction cooker uses this principle to work.

2.The technical principle of the induction cooker program

1. Eddy current theory of induction cooker

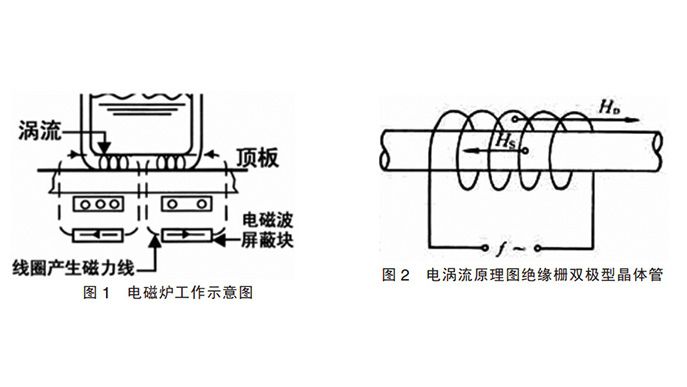

A conductor moving in a magnetic field, or a conductor that is stationary but has a magnetic field that changes with time, can cause the relative cutting of the magnetic field lines and the conductor. As shown in Figure 2, a coil is wound outside a conductor, and the coil is fed with an alternating current, then the coil generates an alternating magnetic field. Since the conductor in the middle of the coil can be equivalent to a closed circuit in a circle in the circumferential direction, the magnetic flux in the closed circuit is constantly changing, so an induced electromotive force and an induced current will be generated in the circumferential direction of the conductor, and the direction of the current is along the circumference of the conductor Turning in circles is like a circle of vortices, so the phenomenon of electromagnetic induction in the whole conductor to generate induced current is called eddy current phenomenon. The eddy current inside the conductor will generate heat. If the resistivity of the conductor is small, the eddy current will be strong and the heat generated will be great.

2. Generation of alternating magnetic field

The current and voltage are converted into direct current through a rectifier, and then through a high-frequency power conversion device, the direct current is converted into a high-frequency alternating current exceeding the audio frequency, and the high-frequency alternating current is added to the flat hollow spiral induction heating coil, thereby generating a high-frequency alternating magnetic field . Its magnetic lines of force penetrate the ceramic platen of the cooktop and act on the metal pot. The pot cuts the alternating magnetic field lines to generate eddy currents in the metal part of the bottom of the pot, so that the iron molecules of the pot move at high speed and irregularly, and the molecules collide and rub against each other to generate heat energy, which is used to heat and cook food, so as to achieve the purpose of cooking.

3. The structural principle of the induction cooker

Structurally, an induction cooker is mainly composed of an electronic part and a structural part. As the name suggests, the electronic part is the electronic components in the induction cooker, including electronic display screen, main board, and coil plate. The structural part is the ceramic plate, fan, power cord and plastic upper and lower covers of the induction cooker. The circuit board inside the induction cooker generates a closed alternating magnetic field by generating high-frequency alternating current to the coil. When the iron cookware is placed in the alternating magnetic field, because of the magnetic properties of iron, the magnetic force of the magnetic field will cause the iron molecules to vibrate, thus forming countless eddy currents, which will cause the iron cookware itself to generate heat, and the heat will be transferred to the Food in the cooker.

The heating principle of the induction cooker can also be understood as a high-frequency transformer. The primary of the high-frequency transformer is the internal coil in the induction cooker, and the secondary is the iron cookware placed on the induction cooker. When the induction cooker is powered on, when the alternating current passes through the coil inside the induction cooker, an induced current is generated on the secondary side, and the current generates heat on the secondary side due to the effect of resistance. If there is no secondary on the induction cooker, that is, the induction cooker does not place iron pans, then the induction cooker cannot function as a "transformer", and the output power will be greatly reduced.

4. The heating principle of the induction cooker

So is it possible that the cooker of any material is placed on the induction cooker, and the induction cooker can generate a heating field with an alternating magnetic field? This requires the analysis of the structure of the induction cooker. The upper contact surface of the induction cooker is a crystal glass plate with high strength and impact resistance. Below the contact surface is the heating coil. The current passes through the heating coil to generate a magnetic field, and the electromagnetic force passes through iron cookware or enamel cookware to generate eddy currents, which heat the cookware itself at a high speed and then pass it to the food. Because the eddy current is generated by the alternating magnetic field, this requires the cooker to have magnetic permeability. The cooker heats up through its own resistance and then transfers it to the food. This also requires that the resistance of the cooker should not be too large, otherwise the heat generated is not enough. Due to its very low magnetic permeability, pure stainless steel products cannot generate large eddy currents on the induction cooker and its magnetic field, and the heating is not ideal. The cookware of the induction cooker is generally ferromagnetic metal or ferromagnetic metal composite. In addition, in view of the radiation that is now being uploaded on the Internet, the electromagnetic field generated by the induction cooker is completely absorbed by the loop formed by the coil and the cooker, so there is no such thing as releasing harmful radiation to the human body.

3. Factors affecting the energy efficiency of induction cooker

During the heating process of the induction cooker, due to the need to go through multiple processes, the generated heat will be lost during the heating process, thereby affecting the energy efficiency of the induction cooker. Judging from the current research, energy loss mainly occurs in four parts: heat conduction, convection, radiation and induction heating, and the main devices involved are as follows.

1. Heat conduction of microcrystalline plate

When the cooking utensils heat up, part of the heat will be conducted to the induction cooker through the microcrystalline plate, resulting in energy loss, which is mainly due to the heat loss caused by the heat conduction effect. The energy loss caused by this reason is closely related to the thermal insulation effect of the microcrystalline board, so the heat loss can be reduced by increasing the thermal insulation performance of the microcrystalline board.

2. The distance between the coil and the pot in the induction cooker

Usually, there is a certain gap between the cooking pot and the plane of the induction cooker, and the width of this gap is actually very small, only 0.5-1 cm. In theory, the smaller the distance between the pan and the coil plane, the higher the energy efficiency of the induction cooker. However, when the distance between the two is too small, the lowest point of the voltage during the LC resonance process is far away from the voltage zero point, which makes it difficult to turn on the IGBT zero point, thereby increasing the energy loss of the IGBT turn-on.

The main function of the coil disk is to generate a changing magnetic field. When a metal vessel is close to the magnetic field, it will cut the magnetic field to generate eddy currents and generate heat. Theoretically speaking, the closer the pot is to the coil plate, the greater the cutting magnetic field density will be, and the more eddy currents will be generated, resulting in greater energy efficiency. However, in actual use, since the coil is close to the pot, the resonance energy is insufficient. When the induction cooker uses low power, most of the energy loss will cause the IGBT to heat up and the energy efficiency will decrease.

3. Energy loss caused by the coil disk

The main parameters of the coil disk are: quality factor (Q), inductance (L) and resistance (R), which is an effective way to heat the coil disk. Among them, the quality factor Q indicates that at a certain frequency, the ratio of the reactance value to the resistance of the coil disk, the larger the value of Q, the smaller the energy loss and the higher the efficiency. The coil is mainly composed of copper wire or aluminum wire. The resistance of the copper wire is smaller than that of the aluminum wire, so the performance of the copper coil is better than that of the aluminum coil. The main function of the magnetic strip in the coil reel is to increase the inductance to avoid the reel being disturbed by the controller. The main material of the magnetic strip is ferrite soft magnetism, and its required characteristics mainly include: high initial permeability ui, high quality factor Q, high stability, and high cut-off frequency fr. Therefore, the magnetic strip often chooses MnZn as the main material.

The energy loss caused by the coil disk mainly includes coil loss and magnetic strip loss. Among them, the reason for the coil loss is mainly: the coil of the induction cooker is mainly composed of stranded wires, and the AC resistance of the stranded wires is smaller than that of solid wires, mainly because when the frequency of the current passing through the wires is relatively high, the current They are all distributed in the outermost conductor of the wire, and the use of multiple twisted wires is equivalent to increasing the cross-section of the conductor, so the AC resistance of the wire is relatively reduced. At the same time, since the twisted wire occupies both the conductor length and the cross-sectional area during fabrication, both the skin effect and the proximity effect are reduced.

The power loss of the coil is mainly manifested in two parts: one is the heat energy generated when the current passes through the coil; the other is the eddy current loss generated by the coil under the alternating magnetic field. In general, thermal power consumption is related to the skin effect of the wire, and the losses caused by the skin effect and the proximity effect can be added. It can be calculated that the energy loss is affected by the number of conductors in the wire, the resistance and the sense resistance.

4. Cooling fan

High-power electrical appliances usually generate a lot of heat during the working process, and this part of the heat cannot be used by the electrical appliances, which is equivalent to doing useless work. As a high-power electrical appliance, the induction cooker will generate a lot of heat during operation. Therefore, it is necessary to install a cooling fan inside the induction cooker to reduce the temperature in the furnace and ensure the normal use of various components in the induction cooker. The extra heat generated by the induction hob during operation cannot be utilized. In order to ensure the normal use of various components in the induction cooker, it is necessary to consume a certain amount of energy to discharge the heat, which causes additional energy consumption during the operation of the induction cooker, which is equivalent to reducing energy efficiency.

4. Solution technology to improve the energy efficiency of induction cooker

The energy consumption analysis of the induction cooker and the method of reducing energy consumption need to be considered as a whole. When the induction cooker is working, multiple parts will affect each other, thereby increasing energy consumption. Only by comprehensively analyzing various factors and finding the best energy consumption and power balance point can the operating energy efficiency of the induction cooker be effectively improved. The power and voltage of the induction cooker are relatively large during operation. Therefore, it is necessary to conduct a comprehensive analysis from the aspects of the pot, platform distance, wire resistance, working power, and coil density to find ways to improve the energy efficiency of the induction cooker while ensuring the safety of use. Energy consumption.

1. Fine-tuning the distance between the induction cooker and the pot

After the analysis of the distance between the coil and the pot, it can be seen that there is a certain relationship between the energy loss and the distance between the pot and the coil. In theory, the smaller the distance, the less energy will be lost, but if the distance is too small, the IGBT will consume more energy. have an impact and increase the energy consumption of the IGBT. Therefore, a comprehensive evaluation of IGBT energy consumption and dissipated energy is required. The study concluded that if the induction cooker is used with high power, in order to prevent excessive heat loss, the distance between the pot and the coil surface can be appropriately reduced, and when low power is used for heating, the distance between the two can be appropriately increased to reduce IGBT energy consumption. Therefore, when relevant personnel conduct research in the future, they can conduct research on the distance between the induction cooker and the pot, and develop a method for fine-tuning the distance to achieve the purpose of reducing energy consumption.

2. Design of magnetic induction coil and magnetic strip of induction cooker

According to the existing data, the size of the conduction resistance is closely related to the skin effect. The greater the frequency of the current passing through the coil, the more obvious the skin effect will be. Therefore, if the diameter of the conductor in the wire is small enough, the resulting conduction resistance will be negligible. In addition, there is a certain distance between the magnetic strip and the induction coil, which will increase the reluctance. Therefore, when designing the magnetic induction coil and the magnetic strip, attention should be paid to the distance between the two to avoid increased energy consumption.

5.The use of induction cooker safety

(1) Since the heating principle of the induction cooker is the heating of the heating appliance itself, care should be taken to leave vent holes for the cooking utensils during use. For sealed appliances, such as cans, direct heating on the induction cooker may cause the sealed products to explode.

(2) The induction cooker needs to use a three-hole socket. Users should pay attention when purchasing, and users must not modify it by themselves. Because the two empty sockets do not have ground wires, they are prone to instant ignition, which is very dangerous for high-power electrical appliances such as induction cookers.

(3) During the use of the induction cooker, be careful not to insert the plug into the socket directly above the induction cooker to avoid damage to the power supply due to the steam generated when the induction cooker heats food.

(4) There are suction ports and exhaust ports for heat dissipation on the bottom shell of the induction cooker. Users should be careful not to block the suction port and exhaust port of the induction cooker during use. It is best to place the induction cooker on a hard table. If there are tablecloths or newspapers on the table, check whether the suction port and exhaust port are blocked. If the induction cooker cannot dissipate heat normally, it may cause the induction cooker to burn out.

(5) After the induction cooker completes the work, it will still retain a certain temperature inside. Therefore, after the induction cooker finishes its work, it is necessary to remove the heated object in time, and place the induction cooker in a position where the air circulates to dissipate heat. This will help prolong the service life of the induction cooker.

(6) Pay attention to the selection of cooking utensils when using the induction cooker to cook food. Cookware must be magnetically permeable and moderately resistant. For example, pure iron utensils, iron alloy utensils with more iron content, or enamel are all acceptable. Ceramics, plastics and other utensils cannot be heated by induction cooker.

(7) While using the induction cooker, do not use electrical appliances with frequent sudden changes in current, such as high-power electrical appliances such as electric welding machines, impact drills, and electric hammers. When using an induction cooker, if these high-power electrical appliances are used at the same time, it is easy to cause damage to the induction cooker. If you want to use these high-power electrical appliances at the same time, you must choose a device with overcurrent protection, or choose a stable power supply.

(8) During the use of the induction cooker, if abnormal shutdowns or alarms occur, you must stop using the induction cooker and contact the manufacturer for timely repair or replacement. Do not disassemble and repair by yourself.

(9) Unplug the power supply when scrubbing the induction cooker, and start scrubbing after the induction cooker cools down. The panel of the induction cooker can be rubbed with cleaning powder, toothpaste or car wax and then wiped with a clean towel; other parts of the induction cooker can only be wiped with a clean soft towel, which can be wiped with water or neutral detergent Then wipe off the residue with a wet towel; do not directly immerse the induction cooker in water for cleaning or rinsing, as this will damage the electronic components of the induction cooker; the suction cover of the induction cooker can be removed and rinsed directly with water; if the induction cooker is not used for a long time, the body needs to be scrubbed clean. Store it after drying. Do not store the induction cooker in a humid environment. You can put some desiccant and cockroach medicine in the storage space.

The above are the details of the induction cooker solution introduced by Shenzhen Zuchuang Microelectronics Co., Ltd. for you. If you have the electronic function development needs of induction cooker, you can rest assured to entrust it to us. We have rich experience in customized development of electronic products, and can evaluate the development cycle and IC price as soon as possible, and can also calculate the PCBA quotation of induction cooker. We are a number of chip agents at home and abroad, including MCU, voice IC, Bluetooth IC and modules, wifi modules. Our development capabilities cover PCB design, single-chip microcomputer development, software custom development, APP custom development, WeChat official account development and other hardware and software design. It can also undertake the research and development of smart electronic products, household appliances scheme design, beauty equipment development, Internet of Things application development, smart home scheme design, TWS scheme development, Bluetooth audio development, children's toy scheme development, and electronic education product development.

- TOP