- Home >> News >> Blog articles >> Appliances & Tools

Development of intelligent range hood control board

With the development of sensor technology and microelectronics technology, people have higher and higher requirements for the control function of range hoods, thus putting forward higher requirements for the control of range hoods. Convenience, durability and multi-function are its development direction. The traditional manual range hoods in the past can no longer meet the development requirements. For this reason, this paper collects signals through gas sensors and thermistors to control the range hood, and designs an intelligent range hood, which is more humanized and convenient to use.

1. Working principle and circuit design of intelligent range hood

The design adopts QM-N10 reducing gas sensor. Its gas-sensitive material is tin dioxide (SnO2), which has low conductivity in clean air. When there is soot in the environment where the QM-N10 sensor is located, the conductivity of the sensor increases rapidly with the increase of the concentration of soot gas in the air under heating. The QM-N10 sensor can convert the change of conductivity into a voltage output signal corresponding to the gas concentration. QM-N10 semiconductor gas sensor has high sensitivity to oil fume gas and can detect various concentrations of oil fume gas.

1.1 Overall circuit design scheme

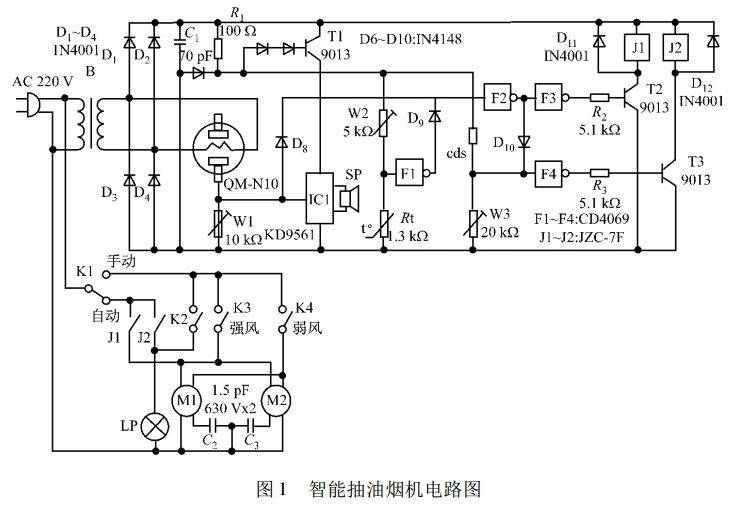

Circuit schematic design shown in Figure 1.

The circuit is composed of QM-N10 sensor, power circuit, integrated NOT gate circuit, triode switch circuit, music alarm circuit, photosensitive sensor circuit, single-phase motor control circuit and so on. After the 220V AC voltage is stepped down by the transformer, rectified by the full bridge, and filtered by the capacitor, it is regulated by the voltage regulator tube to become a 5V DC power supply for the integrated NOT gate circuit, triode switch circuit, music alarm circuit, photosensitive sensor circuit, and QM-N10 sensor circuit. .

When the soot gas in the air reaches a certain concentration, it is detected by the semiconductor gas sensor QM-N10. In the heating state, the resistance between the upper and lower electrodes of the sensor decreases rapidly, and the upper end of the W1 variable resistor in the circuit is caused by the flow of the W1 variable resistor The rapid increase of current makes the potential of this point rise. The potential rise of the upper terminal of the W1 variable resistor makes the output terminal of the non-gate F2 be low level, and the output terminal of F3 becomes high level. When energized, the normally open contact J1 of the J1 relay is closed immediately, and the single-phase motors M1 and M2 are energized to run to extract the oil fume outside. During the daytime, due to the strong light, the cds resistance of the photosensitive resistance sensor is very small, which makes the upper potential of the W3 variable resistor very high, the F4 output terminal becomes low level, and the T3 triode is cut off. The J2 relay coil cannot be energized, and its normally open contact J2 cannot be closed, so the bulb LP cannot be energized during the day. At night, because the light is very weak, the cds resistance of the photosensitive resistance sensor is very large, so that the upper potential of the variable resistor W3 is very low, the output terminal of F4 becomes high level, the T3 triode becomes saturated, and the J2 relay coil is energized. The open contact J2 is closed, so that the light bulb LP is electroluminescent at night and plays the role of lighting.

1.2 Analysis of the working principle of each circuit

(1) Sensor: QM-N10 gas sensor is an N-type semiconductor gas sensor that uses metal oxide semiconductors as sensitive materials. The conductivity of the element increases when it contacts gas. It is characterized by high sensitivity and good selectivity to oil fumes and gas; fast response and recovery characteristics; long life and reliable stability. Its main technical parameters are that the response time is less than 10s, the recovery time is less than 60s, the heating voltage is (5±0.5)V, the heating power is less than 0.5W (the cold state resistance of the heating wire is (50±2)Ω), and the working voltage is 4~ 30V, working temperature is -25~+110°C.

In order to improve the accuracy and reliability, a heating circuit should be provided to maintain the working temperature of the QM-N10 gas sensor when it works normally. Therefore, it must be warmed up for a period of time when using the QM-N10 gas sensor circuit to work normally.

(2) Gas sensor detection circuit: 5V AC voltage directly energizes the heating wire of the QM-N10 gas sensor to make the QM-N10 gas sensor fully heated. When the temperature of the heating wire reaches 200-300°C, the gas sensor is at Normal state; the No. 4 pins H and H of the measuring pole 2 will change with the corresponding gas concentration in the air. The more oil fume gas, the smaller the resistance. W1 (10kΩ) resistor and QMN10 gas sensor A, B are connected in series to form a detection circuit. Adjusting the resistance value of the W1 (10kΩ) resistor can optimize the sensitivity of the circuit to detect gas leakage, and also optimize the sensitivity to detect oil fume gas.

(3) Music alarm circuit: The music alarm circuit is composed of IC1 music circuit chip, transistor T1, and buzzer horn. When there is oil fume or gas leakage, the input end of the music circuit chip is at a high level, and the high level triggers the work of the music circuit chip to make the buzzer horn sound an alarm.

(4) Thermal sensor detection circuit: The thermal sensor detection circuit is composed of W2 (5kΩ) resistor and thermal sensor Rt (1.3kΩ). When the high-temperature cooking fume reaches the thermal sensor Rt, the resistance of the thermal sensor Rt drops a lot, so that the input terminal of F1 non-gate is low level, and the output terminal of F1 non-gate is high level, so the F2 non-gate output terminal is low level, F3 non-gate output terminal is high level, T2 triode is saturated and turned on, J1 relay coil is energized, so that the single-phase motors M1 and M2 run and the oil fume is drawn out of the room. The thermal sensor detection circuit is a bright spot of this range hood, which can greatly increase the detection life. It is an important supplement to the detection circuit of the gas sensor.

(5) Photosensitive sensor detection circuit: The photosensitive sensor detection circuit is composed of W3 (20kΩ) resistor and photosensitive resistor cds. The photosensitive resistor cds has a small resistance under strong light, and a large resistance under light-shading conditions. During the day, the photosensitive resistor cds turns off the diode D10 and makes the output of the F4 non-gate low, and the T3 triode cuts off the bulb LP and cannot light up; at night, the photosensitive resistor cds turns on the diode D10 and makes the output of the F4 non-gate high. The transistor T3 is saturated, and the bulb LP is electroluminescent.

Diodes D11 and D12 are provided to protect transistors T2 and T3. In the manual state, K1 is closed, and the single-phase motors M1 and M2 are not controlled by the above circuit. Closing K3 and K4 can make the single-phase motors M1 and M2 work at high speed and low speed respectively. K2 is used for manually closing LP bulbs.

2. Debugging and installation of intelligent range hood

After the circuit is assembled and checked to be normal, it needs to be debugged: Take a 500mL empty mineral water bottle and tighten the bottle cap. Use a syringe to draw 3 ml of liquefied petroleum gas into the bottle and shake it for a few minutes. At this time, the concentration of liquefied petroleum gas in the bottle is 0.5%. First adjust the W1 variable resistor to the minimum, put the gas sensor into the bottle, then slowly increase the W1 variable resistor until J1 is just closed and the horn sounds an alarm, the W1 variable resistor is adjusted, and then Seal the W1 variable resistor with paint.

Pour another large glass of warm water, the water temperature is slightly higher than the local maximum temperature, put the thermistor into the water, adjust the W2 variable resistor to make J1 just suck in, at this time the W2 variable resistor has also been adjusted, and then the W2 variable resistor Resistor seal. The adjustment of W3 variable resistor should be carried out when the photosensitive resistor cds is shaded. After debugging, open the cover of the range hood, put the control circuit into a plastic box and fix it in an appropriate position in the machine. The gas sensor and photoresistor are installed on the front shell of the range hood, where the oil fume pollution is small. The function switch K1 is installed on the switch plate. The thermistor is glued between the two fans where the hot air is concentrated, and an insulating material is required between the thermistor and the casing. Finally, connect the relay contact with the manual switch of the range hood, install the temperature control circuit and lighting control circuit, place the installation position of the gas sensor, and the debugging and installation work is completed.

Summarize

In this design, the QM-N10N semiconductor gas sensor is used as the oil fume and gas leakage detection sensor, combined with the gas sensor detection circuit, music alarm circuit, thermal sensor detection circuit, and photosensitive sensor detection circuit to realize the function of the intelligent range hood. Through debugging, installation and feasibility experiment, the expected effect of our design has been achieved. It is an intelligent range hood with complete functions and good working performance. Based on the versatility of the gas sensor, it can also be improved according to actual needs. For example, fire alarm, detection and extraction of coal mine gas are all useful.

The above is an example of the development of the control board of the smart range hood introduced by Shenzhen Zuchuang Microelectronics Co., Ltd. If you have a need for range hood solution development, you can trust us. We represent a variety of single-chip microcomputers, voice chips, dual-mode Bluetooth ICs, and wifi chips. Brands include Songhan MCU, Yingguang MCU, Jerry Bluetooth, Ankai Bluetooth, Allwinner, and Realtek. Our technical services include: PCB design, MCU development, Bluetooth solution, software and hardware custom development, APP development, small program development, WeChat official account development, etc. It can also undertake the design of intelligent electronic products, the development of living appliances, the research and development of beauty equipment, the application of Internet of things platform, the smart home control system, the development of TWS earphones, Bluetooth earphone speakers, the development of children's educational toys, the design of electronic education products, etc.

Proposal recommendation

- TOP